|

A guide to self reliant living |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Tuning the Ruger Charger Pistol for accuracy Bug-out-Bag (BOB) Tips and Tricks Bug-out-Bag (BOB) Tips and Tricks

6. Kerosene heaters and cookers

12.

Electrical; generators

Miles Stair's SURVIVAL

Miles Stair's

SURVIVAL |

SURVIVAL RELOADING See also: Home Defense

IF YOU HAVE TO CHOOSE ONLY ONE WEAPON -

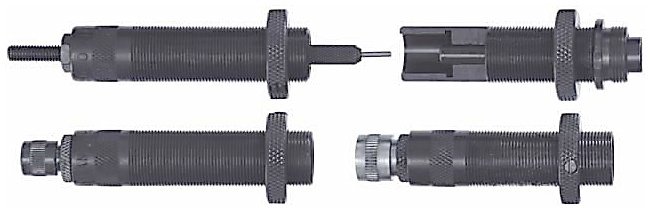

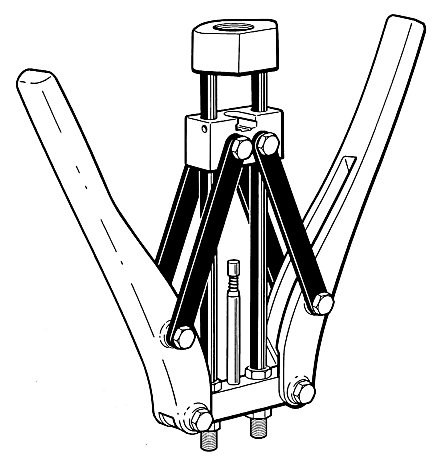

THE BEST HOME DEFENSE .410 SHOTGUN? We are living in perhaps the most difficult time in our nation's history to obtain reloading tools and components. And it is deliberate, as apparently the Department of Homeland Security (an oxymoron) is purchasing everything they can get their hands on by prior contract to keep it out of the hands of the public. Obama lost the battle to get our guns so now he is apparently trying to make them useless without ammunition to shoot. Tools to reload common cartridges are extremely hard to find. It is still possible to find some oddball shell holders and dies, and using the dimension tables below it can be seen that they can be used to reload certain other cartridges. It is not recommended nor ideal to use reloading tools not specifically made for an individual cartridge, but it is far better than the improvised methods of reloading which have been used before in hard times. See the article below on Improvised Reloading to see what people have had to go through without even a modicum of decent reloading equipment. Cartridge Dimensions Below I have listed the relevant dimensions of various center fire cartridges. I can guarantee they are wrong and that I take no responsibility for their use. Why are the dimensions listed below wrong? Because they are "ideal" measurements. Tooling wears as it is used. Every cartridge must have minimum and maximum dimensions. Chamber dimensions must also have minimum and maximum dimensions. It is obvious that the MAXIMUM cartridge must be smaller than the MINIMUM chamber or the odds are that someone, somewhere at some time would purchase cartridges that would not fit into the chamber of his weapon! Neck sizing fired brass to fit a particular chamber is a perfectly useful way of reloading ammunition PROVIDING that brass was previously fired in the same rifle for which it is being reloaded. That does not include semi-auto firearms as their brass must be full length resized. Brass picked up in the field may have been fired in a chamber that was closer to the high end of the maximum dimension permitted and thus would not fit into a minimum-cut chamber without first being full length resized. NECK SIZING PORTABLE EQUIPMENT

FULL LENGTH SIZING PORTABLE TOOLS

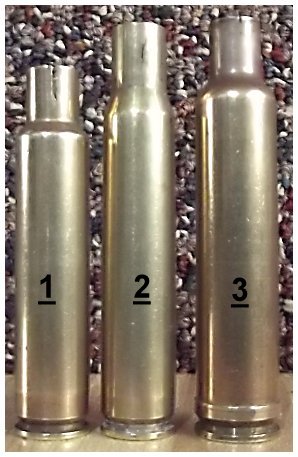

The making of cartridge brass involved expensive draw dies. Whenever possible, draw dies were used to make many different cartridges, the length and caliber being irrelevant as those were formed and trimmed AFTER the basic case was drawn. The rim and extractor groove were also cut and formed after the basic case was drawn. The draw die for .410 brass was used to make the .44 Russian cartridge in the first drawn cases. Later, that same draw die was used to make .303 British, .30-40 Krag, then the .44 Special and much later the .44 Magnum. The base or web of each of those cartridges is essentially the same, with only the rim being of various widths. The overall length of the drawn case is irrelevant to a shell holder.

Neck sizing, full length sizing and case forming There is nothing wrong with neck sizing only. The cases must have been fired in the chamber into which they will be fired when reloaded, but that is not a handicap so long as pressures are kept at close to factory specifications (SAAMI standards) or lower so the action does not compress and thus lengthen the case. As the shoulder is not touched when neck sizing, the headspacing is not changed at all. In fact, neck sizing of rimmed or belted cases generally results in prolonged case life because then the shoulder IS properly headspaced in the chamber because rim or belt IS the headspace "gauge" in rimmed and belted cases, not the shoulder as in rimless cases.

Neck Splits

Now we can look at the dimension tables to find how they are useful. A shell holder cut to fit the smallest rim diameter, the .44 Special and Magnum, will not accept a .303 or .30-40 Krag case because the cut for the rim diameter is too small. Conversely, a shell holder cut for the largest rim, the .30-40, will accept any of the cartridges from that family of cases with smaller rims. That means a #5 adaptor ring for a .310 Tong Tool will accept any of those cases, and an RCBS # shell holder will work for all of them. "Standard" 30-06 cases also have various widths of rims, even if they are rimless cases. Looking at the dimensions listed below, it is clear that the widest rim is the 0.474" rim on the 7.65 Belgian Mauser. The smallest rim is that of the .280 Remington at 0.470. Therefore, a shell holder for a 7.65 Belgian Mauser (or 6.5 x 55 Swede) will accept any ‘06 based cartridge case whereas a tight shell holder for a .280 Remington would not. The same holds true for normal belted magnum cartridges. The 7 x 61 S&H has a rim diameter of 0.534". The other standard-sized belted magnum cases range down to 0.530" diameter. If packing equipment for survival reloading, the shell holder for a 7.61 S&H would be the one to choose as it will accept the other belted magnums. Now look at base diameters of 0.379". The .38 Special was one of the first using this draw die, followed by the .222 and .223. For neck sizing versatility, to see what size die will neck size other cartridges, the length to neck, shoulder diameter and neck diameter are all important. The body of the case to be sized must have a shoulder diameter larger than the case to be sized and the body of the case must be the same as or longer than the parent die. A .308 Win has a neck size die can size the necks of 300 Savage, .30-40 and .30-06 when sized properly to hold bullets of 0.308" diameter, for example. A .222 Rem die can be backed out and size the necks of .222 Rem Magnum and .223's/5.56's. It is best to have complete, original die sets for every cartridge for which you intend to reload, but for survival reloading there are a few shortcuts that can be made. If you can keep a neighbor’s weapon working that lessens his desire for YOUR rifle or handgun.

Name/designation of cartridge A. Rim diameter B. Base or Web Diameter C. Length to neck D. Shoulder diameter E. Outside neck diameter F. Overall length G. Bullet Diameter

======== IMPROVISED RELOADING - DOING IT THE HARD WAY The book "American Guerilla In The Philippines," by Ira Wolfert (Simon & Shuster, 1945), is the story of one American naval officer who escaped the Bataan Death March, became a resistance leader while managing to survive behind enemy lines for 4 years. The resistance had virtually nothing. They found a few old Springfield rifles, but only 3,000 rounds of empty brass. To defend themselves against the vicious invaders they had no choice but to make their own ammunition as best they could. For bullets, brass curtain rods were cut to length, filed down, driven through an old Springfield barrel to swage them to size, then filled with molten lead scrounged from old auto battery plates. This resulted in bullets that were not of uniform size or weight and did not have a point or ogive, and thus would not feed through the magazine.

For primers, they made a punch to knock out the fired primer. The anvil was picked out and saved. Then a drill rod was used to pound flat the firing pin indentation. Sulfur was then mixed with coconut shell carbon and some antimony powder, tamped into the primer, and the anvil replaced (NOT for the faint of heart!). The primer pocket crimp on the G. I. brass was cut out with a pocket knife, then the case was placed over the primer and a dowel placed in the case and rapped with a mallet until the primer was seated. For powder, they took powder from unexploded Japanese sea mines, then added pulverized wood as a filler in a vain attempt to retard the burning rate. The powder was then poured through a funnel into the primed cases until "it looked like enough." The bullets were crimped into the case mouths with a pair of pliers. Each round had to be tried in a rifle, and if it didn't fit then it was crimped again with pliers in various places until it fit. This process was so laborious that sixty soldiers worked full time on it and "never got better than an average of 160 bullets a day," and at best only 80% of the cartridges fired. It worked to a degree, but that was pathetic reloading. It does vividly illustrate why reloading equipment is vital to survival in some adverse situations! If those guerrilla's had the portable equipment listed in my booklet "Survival Reloading," three soldiers could have produced thousands of rounds of virtually perfect ammunition per day. They could have used 32 S & W dies to neck size and reload .303 British, 7.7 Jap and 30 caliber cartridges when using .311 - .312 cast bullets, and 32 ACP dies when reloading all .308 caliber cartridges when using jacketed bullets. And if the lower 3/8" or so of the seating dies was cut off, the bullets could even be crimped in place. With a set of 38 S&W dies, they could have reloaded for every "38" caliber pistol cartridge available in those days. With proper bullet molds, they could have had respectable velocity combined with smooth feeding and excellent accuracy.

For powder they could have burned 1.0 cc of the mine powder, timed it, and then burned 1.0 cc of Red Dot, Herco and 4895 (about the same as any military rifle cartridge powder), then used the "minimum" reloading data for a powder close to the burning rate of the powder they could find not ideal or even recommended, but far better than merely guessing and blowing up rifles. This page is a work in progress and will be completed as time permits.

|

1. Food | 2.

Manna Meals | 3. Water |

4. Sanitation | 5. Medical, health |

| 6. Kerosene heaters and cookers | 7. Lighting | 8. Wood cooking and heating | | 9. Communications | 10. Essential Tools | 11. Home built items | | 12. Electrical; generators and power | 13. War preparedness | 14. Gardening |

| HOME |

PROPHECY

| PREPARATIONS

| QUICKENING

NEWS | COMMENTARY

BY MILES |

| GUEST SUBMISSIONS | BOOKLETS BY MILES | CONTACT INFORMATION | | LINKS | RADIATION INDEX & JET STREAM | DEVOTIONAL ITEMS | | PHOTO INDEX | LIBRARY | SURVIVAL SHOP

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||