|

SITE

INDEX

QUICKENING

NEWS

PREPARATIONS

1.

Food

2.

Manna

Meals

3.

Water

4.

Sanitation

5.

Medical,

health

6.

Kerosene heaters and cookers

7.

Lighting

8. Wood

cooking and heating

9. Communi-cations

10. Essential

Tools

11. Home

built items

12.

Electrical; generators

and power

13. War

preparedness

14.

Gardening

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

HOME

RADIATION

INDEX & JET STREAM

PROPHECY

COMMENTARY

BY MILES

BOOKLETS

BY MILES

GUEST

SUBMISSIONS

PHOTO

INDEX

LINKS

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

|

|

Using Lyman 310 Tong

Tools for Reloading

I purchased my first

Lyman Tong Tools in 1964 so I could do load development work

at the range. They worked so well I expanded the

selection of dies to include all of my most popular

cartridges, and the handles, dies, loading blocks, primer

flipper and Lee Dipper Set all fit into a single 50 caliber

ammo box. Yes, they neck size only and some people like

to denigrate 310 tools for that supposed deficiency, but in

many cases neck sizing is all that is needed for bottle neck

cases. Lyman 310 Tong Tools do full length resize

straight sided cases for pistols and revolvers.

If pressures are kept to

SAAMI standards, neck sizing is sufficient for bottle necked

cartridges which have been previously fired in that chamber.

The very unique Lyman "M" die, also called the neck expanding

die, is a fabulous design which is fantastic when reloading

using cast bullets. Loads for cast lead bullets are

almost by definition mild pressure loads: Brass lasts

virtually forever and so do rifle barrels. And cast

bullets cost only a fraction of the per-cost shot compared to

using jacketed bullets.

|

This section of

photos was scanned from an old Lyman brochure for using

the Lyman 310 Tools. It was a small brochure and

old, so the wording was difficult to scan to make it easy

to read. I have typed in the exact wording in this

column to make it easier to read.

These instructions are far from

complete. I have added NOTES below the relevant sections

for additional tools that make reloading vastly easier and

much more organized. |

|

|

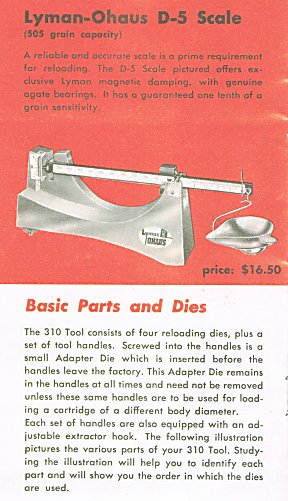

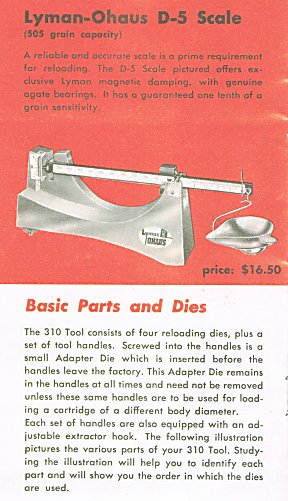

Lyman-Ohaus D-5 Scale

A reloading scale is extremely

nice to have. I prefer the Ohaus scale that fits neatly

into the base and has a protective cover. My scale

was purchased in 1964 and is still in perfect condition,

thanks, I am sure, to the easy storage system.

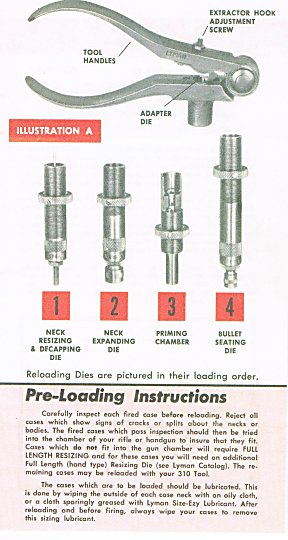

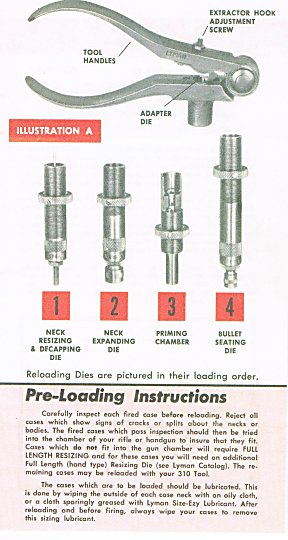

Basic Parts and Dies

The 310 Tool consists of four

reloading dies, plus a set of tool handles. Screwed into

the handles is a small Adapter Die which is inserted

before the handles leave the factory. This Adapter Die

remains in the handles at all times and need not be

removed unless the same handles are to be used for

loading a cartridge of a different body diameter. Each set

of handles are also equipped with an adjustable extractor

hook. The following illustration pictures the various

parts of your 310 Tool. Studying the illustration will

help you identify each part and will show you the order in

which the dies are used. |

|

`

|

Pre-Loading

Instructions

Carefully inspect each fired case before reloading.

Reject all cases which show signs of cracks or splits

about the necks or bodies. The fired cases which pass

inspection should then be tried into the chamber of your

rifle or handgun to insure that they fit.

Cases which do not fit into the gun chamber will require

FULL LENGTH RESIZING and for these cases you will need an

additional Full Length (hand type) Resizing Die (see Lyman

Catalog). The remaining cases may be reloaded with

your 310 tool.

The cases which are

to be loaded should be lubricated. This is done by

wiping the outside of each case neck with an oily cloth,

or a cloth sparingly greased with Lyman Size-Ezy

Lubricant. After reloading and before firing, always

wipe your cases to remove the sizing lubricant.

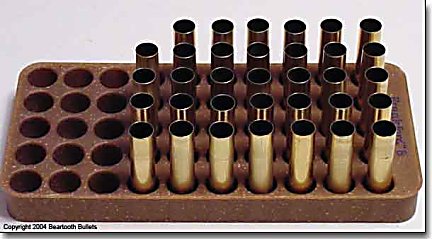

NOTE:

It is far better to use a large stamp pad for lubricating

the case necks. A cloth-covered felt pad in a stamp

pad can be carefully scraped clean with a knife to remove

debris. After a decade of use the stamp pad

cover will become worn. The cover can be removed and

replaced with a section of finely-woven handkerchief

material. I use

Neatsfoot Oil as a lubricant. Each lubricated

case is then set in a loading block (see below).

|

|

`

|

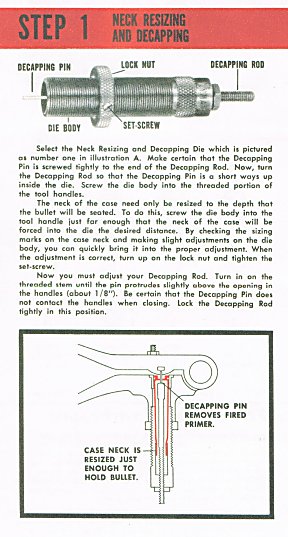

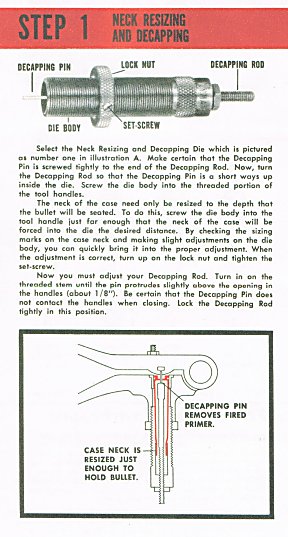

Step 1 Neck Resizing and Decapping

Select the Neck

Resizing and Decapping Die which is pictured as number one

is illustration A. Make certain that the Decapping Pin is

screwed tightly to the end of the Decapping Rod.

Now, turn the Decapping Rod so that the Decapping Pin is a

short ways up inside the die. Screw the die body

into the threaded portion of the tool handles.

The neck of the case need only be resized to the depth

that the bullet will be seated. To do this, screw

the die body into the tool handle just enough that the

neck of the case will be forced into the die the desired

distance. By checking the sizing marks on the case

neck and making slight adjustment to the die body, you can

quickly bring it into the proper adjustment. When the

adjustment is correct, turn up the lock nut and tighten

the set-screw.

Now you must

adjust the Decapping Rod. Turn in on the threaded

stem until the pin protrudes slightly above the opening in

the handles (about 1/8"). Be certain that the Decapping

Pin does not contact the handles when closing. Lock

the Decapping Rod tightly in this position.

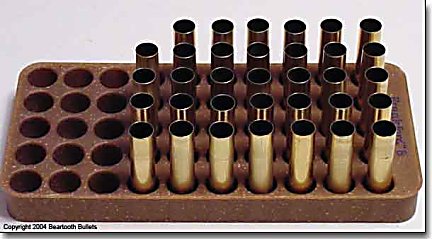

NOTE: For this procedure

you should have two Loading Blocks, moving each lubricated case as it

is necksized into the other block.

|

|

|

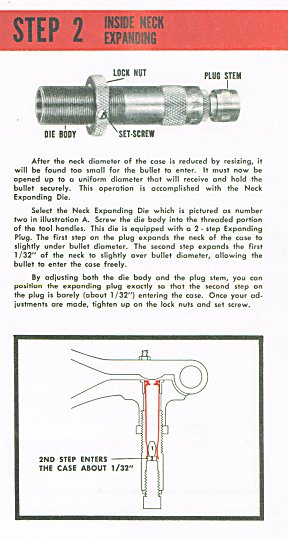

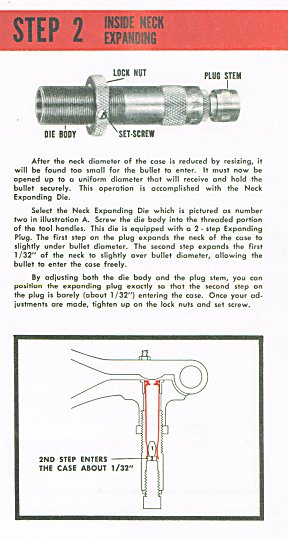

STEP 2 INSIDE NECK EXPANDING

After the neck diameter of the case is reduced by

resizing, it will be found too small for the bullet to

enter. It must now be opened up to a uniform diameter that

will receive and hold the bullet securely. This operation

is accomplished with the Neck Expanding Die.

Select the Neck Expanding Die which is pictured as number

two in Illustration A. Screw the die body into the

threaded portion of the tool handles. This die is equipped

with a 2-step Expanding Plug. The first step on the plug

expands the neck of the case to slightly under bullet

diameter. The second step expands the first 1/32" of

the neck to slightly over bullet diameter, allowing the

bullet to enter the case freely.

By adjusting both the die body and the plug stem, you can

position the expanding plug exactly so that the second

step on the plug is barely (about 1/32") entering the

case. Once your adjustments are made, tighten up on the

lock nuts and set screw.

NOTE: Before the lock ring is

set, try a bullet base in the case mouth to ensure it fits

into the short expanded section. This is extremely

important, especially when loading cast bullets. When

finished with all the cases, carefully wipe each case with

a dry cloth to remove all lubricant.

This die can often be used for any cartridge of the same

diameter, ie, a .308 size expander die will expand the

neck of virtually all .30 caliber cases. |

|

`

|

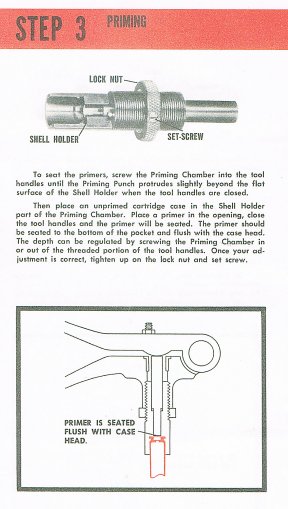

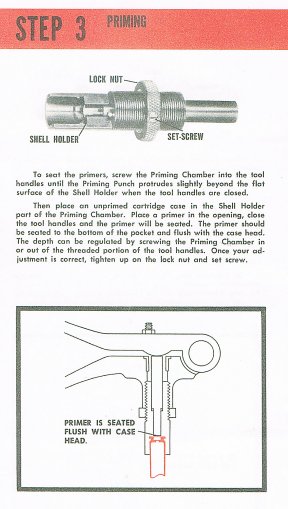

STEP 3 PRIMING

To seat the primers, screw the Priming Chamber into the

tool handles until the Priming Punch protrudes slightly

beyond the flat surface of the Shell Holder when the tool

handles are closed.

Then place an

unprimed cartridge case in the Shell Holder part of the

Priming Chamber. Place a primer in the opening, close the

tool handles and the primer will be seated. The primer

should be seated to the bottom of the pocket and flush

with the case head. The depth can be regulated by screwing

the Priming Chamber in or out of the threaded portion of

the tool handles. Once your adjustment is correct, tighten

up on the lock nut and set screw.

NOTE: It is far easier

to hold the Tong Tool so the die body is off to one side,

not straight down as illustrated at right. Set a primer in

the groove, then a case in the shell holder, and close the

handles to seat the primer.

Primers are not fungible: use the proper primer for the

case being reloaded - small primer for pistol or revolver

cases using a .175" primer, a large pistol primer for

cases like .44 Special using a .210" diameter primer, and

rifle primers by size in the appropriate cases. Pistol

primers are softer and cannot handle the pressures

developed in rifle cases, and often a harder rifle primer

cannot be ignited by the firing pin of a pistol or

revolver. |

|

|

CHARGING A CASE WITH POWDER

This step is completely missing from the

factory instructions for 310 Tools. Smokeless powder can

be measured or weighed, or a combination of the two can be

used.

For easy, portable reloading, a Lee Powder Measure set can

work well. A loading manual for the cartridge you are

reloading is mandatory to give you the powder charge

weights by cartridge and bullet weight you are using, AND

a listing of the powder weight for each Lee Dipper is

imperative. I have those tables listed for three

different smokeless powders in my

Survival Reloading booklet.

A

Powder Scale weighs each powder charge in grains and is

the most accurate method of loading powder, but is slow.

When using either a dipper or scale, the powder is poured

into a cartridge case using a Powder Funnel.

A Powder Measure

is adjustable and "throws" a measure of powder by volume.

The volume of powder then must be weighed on a powder

scale and the drum on the powder measure adjusted until it

"throws" the same volume (and therefore weight) of powder

each time the handle is turned to fill up the drum from

the powder hopper. When properly adjusted, cases can

be charged with powder directly from a Powder Measure, BUT

the throw weight should be checked on a Powder Scale every

10th or 20th charge.

|

Lee Powder Dippers

Lee Powder Dippers

Ohaus Powder Scale

Ohaus Powder Scale

RCBS Powder Measure

RCBS Powder Measure

Powder Funnel

Powder Funnel |

|

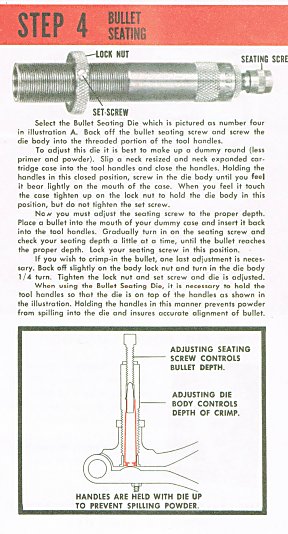

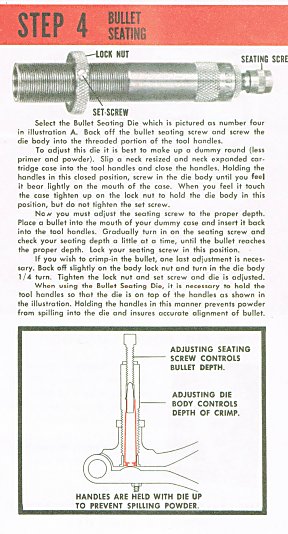

STEP 4 BULLET SEATING

Select the Bullet Seating Die which is pictured as number

four in illustration A. Back off the bullet seating screw

and screw the die body into the threaded portion of the

tool handles.

To adjust this die

it is best to make up a dummy round (less primer and

powder). Slip a neck resized and neck expanded cartridge

case into the tool handles and close the handles. Holding

the handles in this closed position, screw in the die body

until you feel it bear lightly on the mouth of the case.

When you feel it touch the case tighten up on the lock nut

to hold the die body in this position, but do not tighten

the set screw.

Now you must

adjust the seating screw to the proper depth. Place a

bullet into the mouth of your dummy case and insert it

back into the tool handles. Gradually urn in on the

seating screw and check your seating depth a little at a

time, until the bullet reaches the proper depth. Lock your

seating screw in this position.

If

you wish to crimp-in the bullet, one last adjustment is

necessary. Back off slightly on the body lock nut and turn

in the die body 1/4 turn. Tighten the lock nut and set

screw and the die is adjusted.

When using the Bullet Seating

Die, it is necessary to hold the tool handles so that the

die is on top of the handles as shown in the illustration.

Holding the handles in this manner prevents powder from

spilling into the die and insures accurate alignment of

the bullet.

NOTE: Crimping the bullet is

not needed when loading for bolt action rifles. |

|

`

Ideal #310 Tool Quick Reference - Rifle

CTG

|

Handle |

Adapter

|

Priming

|

MR - DA

|

Exp Chamb

|

Exp - Cast

|

Exp - Jack

|

Seat - Cast

|

Seat - Jack

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

218 Bee |

S |

3 |

10 |

172 |

R-S |

0.225 |

0.224 |

438 |

450 |

|

219

Wasp |

L |

6 |

6 |

171 |

R-S |

0.225 |

0.224 |

438 |

450 |

|

219

Zipper |

L |

6 |

6 |

171 |

R-M |

0.225 |

0.224 |

438 |

450 |

|

22

Hornet |

S |

4 |

4 |

165 |

R-S |

0.224 |

0.224 |

438 |

450 |

|

22 K

Hornet |

S |

4 |

4 |

165 |

M-S |

0.224 |

0.224 |

438 |

450 |

|

22/250

Var. |

L |

2 |

2 |

22/250 |

R-M |

0.225 |

0.224 |

438 |

450 |

|

22

Lovell |

S |

12 |

19 |

173 |

M-S |

0.225 |

0.224 |

438 |

450 |

|

22 Sav

H. |

L |

6 |

6 |

141 |

R-M |

0.228 |

0.225 |

367 |

367 |

|

220

Swift |

L |

5 |

5 |

169 |

R-M |

0.224 |

0.224 |

438 |

450 |

|

222 Rem. |

S |

1 |

26 |

222 |

R-M |

0.225 |

0.224 |

438 |

450 |

|

25/20

Rept. |

S |

3 |

10 |

10 |

R-S |

0.257 |

0.257 |

420 |

420 |

|

25/35 |

L |

6 |

6 |

11 |

R-M |

0.257 |

0.257 |

325 |

325 |

|

25 Rem. |

L |

6 |

15 |

133 |

R-M |

0.257 |

0.257 |

325 |

325 |

|

250/3000 |

L |

2 |

2 |

143 |

R-M |

0.257 |

0.257 |

388 |

418 |

|

257

Robt. |

L |

2 |

8 |

166 |

R-M |

0.257 |

0.257 |

388 |

418 |

|

6.5 Jap |

L |

2 |

2 |

137 |

R-M |

0.266 |

0.263 |

469 |

418 |

|

6.5

Mann. |

L |

5 |

5 |

137 |

R-M |

0.266 |

0.263 |

469 |

418 |

|

270

Win. |

L |

2 |

2 |

153 |

R-L |

0.280 |

0.277 |

468 |

411 |

|

7 m/m |

L |

2 |

2 |

116 |

R-M |

0.287 |

0.285 |

448 |

377 |

|

30

Carbine |

S |

15 |

23 |

29 |

R-S |

0.309 |

0.308 |

8 |

359 |

|

30/30 |

L |

6 |

6 |

13 |

R-M |

0.311 |

0.308 |

241 |

241 |

|

308

Win. |

L |

2 |

2 |

146 |

R-M |

0.311 |

0.308 |

413 |

329 |

|

300 Sav. |

L |

2 |

2 |

146 |

R-M |

0.311 |

0.308 |

466 |

414 |

|

30/40 |

L |

5 |

7 |

15 |

R-M |

0.311 |

0.308 |

467 |

329 |

|

30/06 |

L |

2 |

2 |

123 |

R-L |

0.311 |

0.308 |

413 |

329 |

|

300 H.

& H. |

L |

8 |

13 |

168 |

R-L |

0.311 |

0.308 |

467 |

329 |

|

7.62

Russ. |

L |

10 |

16 |

163 |

R-L |

0.311 |

0.308 |

413 |

329 |

|

303 Sav. |

L |

5 |

5 |

16 |

R-M |

0.311 |

0.308 |

241 |

329 |

|

303

Brit. |

L |

5 |

7 |

17 |

R-M |

0.313 |

0.311 |

299 |

299 |

|

7.7 Jap |

L |

2 |

2 |

146 |

R-M |

0.311 |

0.308 |

413 |

329 |

|

32/20 |

S |

3 |

10 |

29 |

R-S |

0.311 |

0.308 |

8 |

8 |

|

32/40 |

L |

6 |

6 |

28 |

R-M |

0.321 |

0.319 |

232 |

232 |

|

32

Spec. |

L |

6 |

6 |

97 |

R-M |

0.321 |

0.319 |

297 |

317 |

|

8 m/m |

L |

2 |

2 |

118 |

R-M |

0.323 |

0.323 |

470 |

366 |

|

33 Win. |

L |

10 |

17 |

98 |

SPC |

0.338 |

0.338 |

320 |

320 |

|

348

Win. |

SPC |

11 |

18 |

170 |

SPC |

0.350 |

0.350 |

447 |

447 |

|

35 Rem. |

L |

5 |

20 |

128 |

SPC |

0.358 |

0.356 |

315 |

315 |

|

35 Win. |

L |

5 |

7 |

124 |

SPC |

0.358 |

0.356 |

318 |

318 |

|

9 m/m

rifle |

L |

11 |

2 |

126 |

SPC |

0.358 |

0.356 |

238 |

238 |

|

375 H.

& H. |

L |

8 |

13 |

162 |

SPC |

0.375 |

0.375 |

449 |

449 |

|

38/40 |

S |

9 |

14 |

42 |

R-S |

0.401 |

0.401 |

43 |

43 |

|

38/55 |

L |

6 |

6 |

44 |

SPC |

0.379 |

xxx |

296 |

xxx |

|

401

Win. |

S |

16 |

2 |

147 |

R-M |

0.412 |

xxx |

426 |

xxx |

|

405

Win. |

L |

2 |

7 |

121 |

R-L |

0.412 |

xxx |

263 |

xxx |

|

44/40 |

S |

9 |

14 |

78 |

R-S |

0.427 |

xxx |

98 |

xxx |

|

45/70 |

L |

10 |

17 |

89 |

R-L |

0.457 |

xxx |

124 |

xxx |

|

45/90 |

L |

10 |

17 |

89 |

R-L |

0.457 |

xxx |

191 |

xxx |

Ideal #310 Tool Quick Reference - Pistol

CTG

|

Handle

|

Adapter

|

Priming

|

MR - DA

|

Exp Chamb

|

Exp - Cast

|

Exp - Jack

|

Seat - Cast

|

Seat Jack

|

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|

30

Luger |

S |

17 |

12 |

120 |

P-S |

0.311 |

xxx |

244 |

xxx |

|

32 S. &

W. L. |

S |

3 |

9 |

122 |

P-S |

0.313 |

xxx |

226 |

xxx |

|

32

Auto. |

S |

3 |

9 |

SPC |

P-S |

0.312 |

xxx |

252 |

xxx |

|

32 S. &

W. |

S |

3 |

9 |

22 |

P-S |

0.313 |

xxx |

249 |

xxx |

|

32/20 |

S |

3 |

10 |

29 |

P-S |

0.311 |

xxx |

8 |

xxx |

|

357 Mag. |

S |

1 |

3 |

95 |

SPC |

0.357 |

xxx |

446 |

xxx |

|

9 m/m

Luger |

S |

17 |

12 |

134 |

SPC |

0.356 |

xxx |

402 |

xxx |

|

38

Auto. |

S |

17 |

12 |

119 |

SPC |

0.358 |

xxx |

242 |

xxx |

|

38 Spc. |

S |

1 |

1 |

95 |

SPC |

0.358 |

xxx |

311 |

xxx |

|

380

Auto. |

S |

17 |

12 |

144 |

SPC |

0.358 |

xxx |

242 |

xxx |

|

38/40 |

S |

9 |

14 |

42 |

SPC |

0.401 |

xxx |

43 |

xxx |

|

41 Long |

S |

14 |

25 |

72 |

P-S |

0.386 |

xxx |

178 |

xxx |

|

44

Russ. |

S |

9 |

7 |

150 |

P-S |

0.429 |

xxx |

251 |

xxx |

|

44

Spec. |

S |

9 |

7 |

150 |

P-S |

0.429 |

xxx |

421 |

xxx |

|

44/40 |

S |

9 |

14 |

78 |

P-S |

0.427 |

xxx |

98 |

xxx |

|

45

Auto. Rim |

S |

7 |

17 |

127 |

P-S |

0.452 |

xxx |

423 |

xxx |

|

45

Auto. |

S |

7 |

2 |

127 |

P-S |

0.452 |

xxx |

374 |

xxx |

|

45 Colt |

S |

7 |

11 |

86 |

P-S |

0.454 |

xxx |

190 |

xxx |

|

|

|