Tuning the Ruger Charger

Pistol

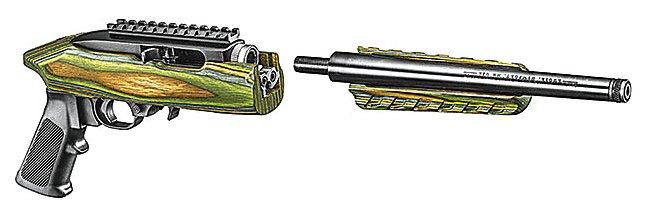

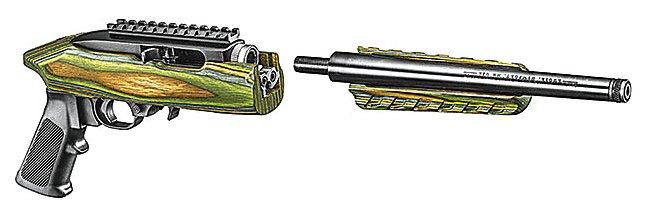

The work shown features a

Ruger Charger Pistol take-down model in the illustrations but virtually all

aspects of the various parts tuning and action bedding applies equally to

the 10/22 rifle in both standard and take-down models. For a more

detailed view, click on each illustration to see the enlargement.

|

The Ruger Charger take-down model has

the potential to be an outstanding survival weapon because it takes down

into two parts, neither of which exceed 11 inches in length and will fit

into a compact carry case. Based on the proven reliable 10/22 rifle

action, they have the potential to be accurate. As sold by Ruger,

however, the actions are roughly machined. With a little time and effort

they can be accurized. My Charger would not shoot better than 2 ½'’

groups at 25 yards so it really needed to be tuned up.

The trigger

pull on my Charger was 6 ½ lbs of gritty, overly-long travel. Two pins

and the trigger group was removed from the action and ready for work.

|

|

|

|

TRIGGER WORK

Above left, the trigger group has been removed from the

action. That only entails the removal of two pins. Then the two

highest pins on the trigger group are removed so the hammer, hammer spring,

ejector and hammer spring can be removed. Above right, the pin holding

the trigger and sear has been removed and those parts shown in the order in

which they fit together. Don't lose that small spring!

IT IS TIME TO DO SOME POLISHING

The hammer (above left) and the

trigger sear (above right) appear to be rough investment castings. I

flat-sanded every flat surface with 200 grit emery, then repeated the

process with 400 grit emery. There are many Youtube videos showing how to

file the sear notches to lighten the trigger pull.

MODIFYING THE BOLT HOLD-OPEN LEVER

While the trigger group is apart is a

good time to work on the bolt hold-open lever. The

factory bolt hold-open lever is double-duty and must be manipulated to

release the bolt to travel forward. A hot aftermarket item is an automatic

bolt release.

Look at the illustrations at right and

you will see that a chainsaw file can easily remove some metal so the bolt

release is automatic. How much to file down? The point in the

left photo above must be filed down and the "web" remaining between the new

hole should be the same thickness as the web on the small hole on the left

side. Now when you pull the bolt back it is free to slide forward

automatically without fumbling with the small release lever. This

modification just saved $20.00, the cost of a new replacement automatic bolt

release.

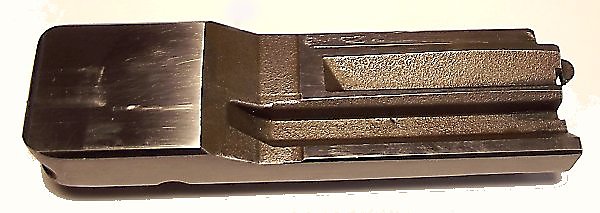

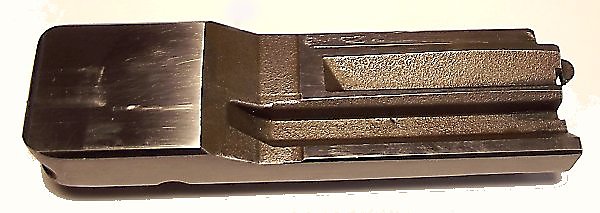

FLAT SAND THE BOLT

|

The bolt was roughly

machined and any roughness leads to dirt & grit accumulation, to say

nothing of creating friction on bearing surfaces. At right is the top of

the bolt. It was polished mirror bright, then a brick of ammo fired. The

wear marks are clearly visible in the polished surface. |

|

|

At right, the bottom of

the bolt. Note the visible wear marks where the flat bottom of the bolt

cocked the hammer during recoil after each shot. The surface was mirror

smooth, as was the mating hammer surface. Without polishing those two

surfaces would have created considerable friction. |

|

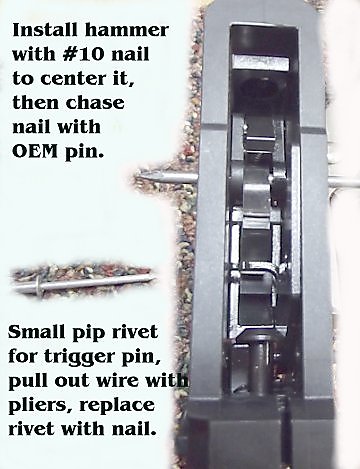

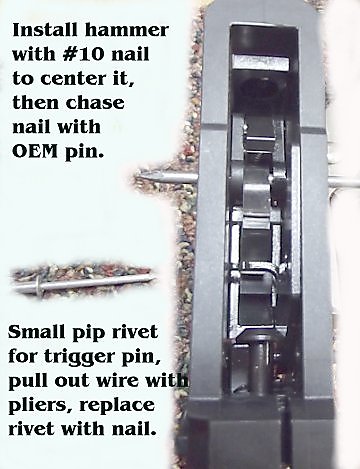

REASSEMBLY OF THE TRIGGER GROUP

|

Reassembly of the trigger and sear

can be difficult. I used Scotch Tape to hold the trigger return spring

and plunger in as the trigger and sear were positioned in place. There

is nothing to hold the two sear levers in place but there is a small

spring to pop them apart, so I used a 22 gauge wire to hold the two

pieces together and the spring compressed while lowering the trigger

group into the trigger housing. A thin nail will fit through the hole

for the trigger pin with room for the copper wire to hold the assembly

in place. The wire can then be pulled out with pliers and the thin nail

chased out of the pin hole with the proper pin. |

|

|

At right the trigger group is

being reassembled. Small nails are used to hold the parts in place, then

the small nails "chased" from the holes by the proper pins. It just

makes things easier. There are many Youtube videos showing the

step-by-step reassembly process.

Before the trigger group can be reinstalled in the

action, the bolt needs to be flat sanded to eliminate all possible

friction to maximize action life and eliminate chances for parts

breakage. Ruger sells a replacement "BX trigger" for $75.00, and I

bought one. Long, gritty pull and not crisp at all. The trigger I

modified as shown here has a 3 lb pull with a crisp let-off, much better

than the BX trigger. |

|

MAKING A BUFFERED BOLT STOP/RECOIL PIN

|

The OEM bolt stop pin is 1/4" x 1

1/4" of solid steel. When the bolt recoils hard from the use of high

velocity ammo, the back of the bolt slams into that pin. Buffered pins

are sold as aftermarket items but it easy to make them. At right is a

1/8'’ hardened steel roll pin and a 1/4'’ vinyl hose with a 1/8'’ hole

in the middle. Push the roll pin through the hole in the hose and the

result is a savings of $10 to $20 for an aftermarket pin. |

|

It is now time to reassemble the

action and install it in the stock. There are Youtube videos which show the

step-ty-step process of reassembly, if needed.

THE ACTION IS NOW SMOOTH AND THE

TRIGGER PULL LIGHTENED

|

The Charger was reassembled and

tested. Bad news. Now that it was easier to test for accuracy, shooting

groups instead of patterns, the groups showed a distinct vertical

spread.

Group showing the barrel needs to be bedded. The

forearm had too much upward pressure on the barrel so wood was removed

to free-float the barrel, then glass bedded. |

|

|

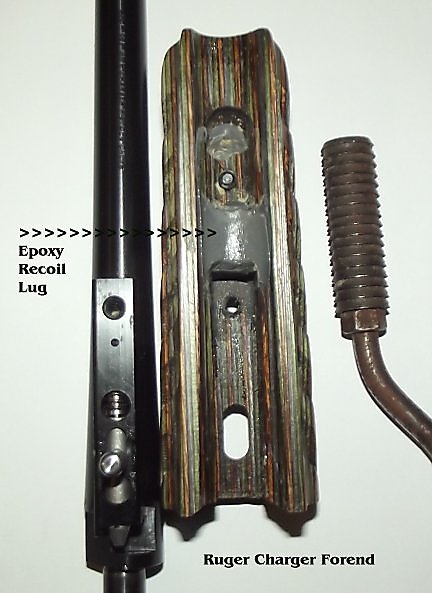

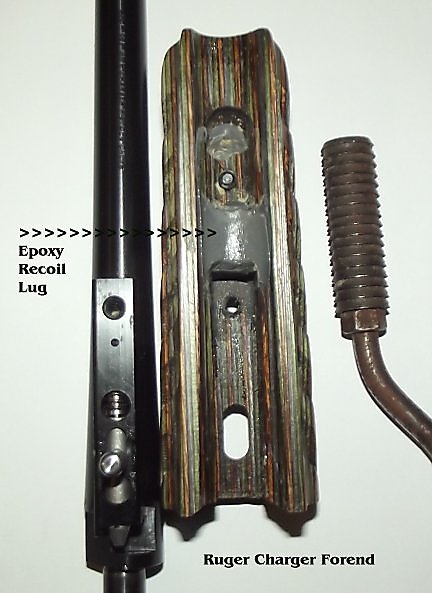

The forend on the Ruger Charger takedown has a

deep groove all the way from the action to past the sling swivel screw. There

is no recoil lug at all! Plumber’s putty was used to make dams between the

action screw and sling swivel screw to contain the bedding compound, and JB

KWIK Weld put between the two dams to

form a recoil lug to hold the forend securely against the barrel.

THE ACTION NEEDS BEDDING

|

Bench rest shooting with a

now-smooth action and trigger and bedded forend eliminated the distinct

vertical group stringing. The horizontal spread shows the action needed

to be bedded. The action screw was examined and was too long (bearing

against the barrel tightening band) so it was shortened 1/8" to properly

pull the action firmly into the stock. |

|

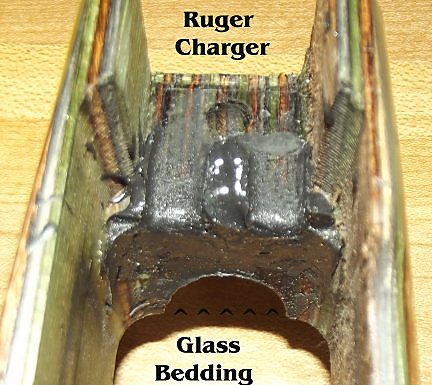

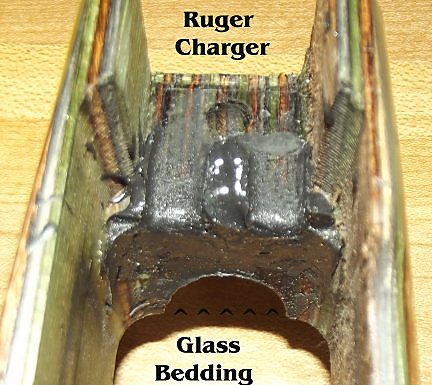

BEDDING THE ACTION (Remove the

trigger group BEFORE glass bedding.)

|

|

|

|

| Wood removed for recoil lug |

Recoil lug glass bedded |

The rear of the action

bedded |

Note the photo above right. The area

of bedding that is rough, right in the lower center, must be filed back a

bit to clear the trigger group. Had the trigger group not been removed

it would have been glassed solidly into the stock forever when the

glassbedding compound extruded from the rear of the action. With the

action now firmly bedded into the stock it cannot move and shift position

during recoil.

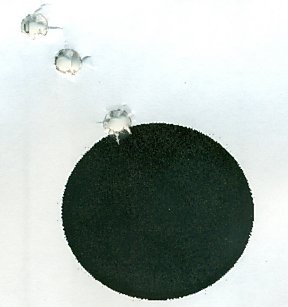

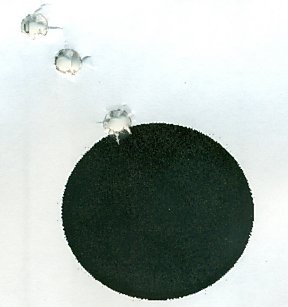

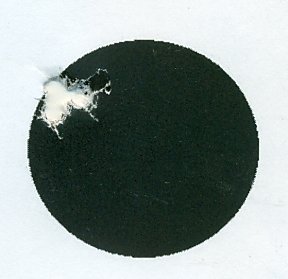

AFTER ALL THE TUNING AND BEDDING

|

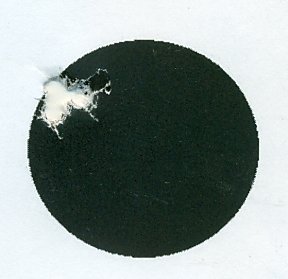

It was all worth it. The group

shown at right was shot at 25 yards from a bench rest. All three holes

touch. Shooting conditions were abysmal with wind, rain and failing

light. That is a good group considering the weather conditions and a

cheap 2X forward eye relief scope. This Ruger Charger now shoots well

enough to justify replacing the scope with a quality 2x - 6x pistol

scope to extend the range potential for accurate shot placement.

Accurate shot placement plus the ability to lay down a withering barrage

of fire from high capacity magazines makes the Charger a very versatile

pack pistol. |

|

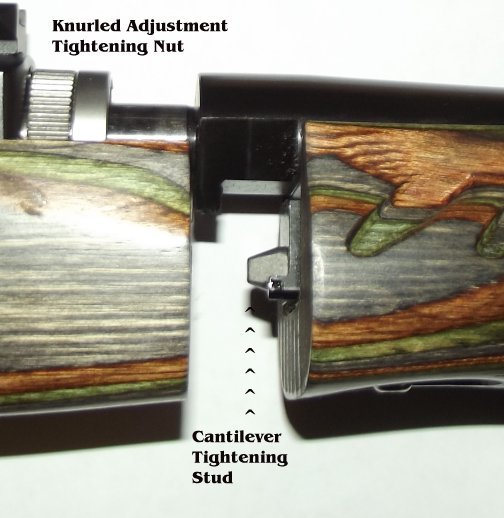

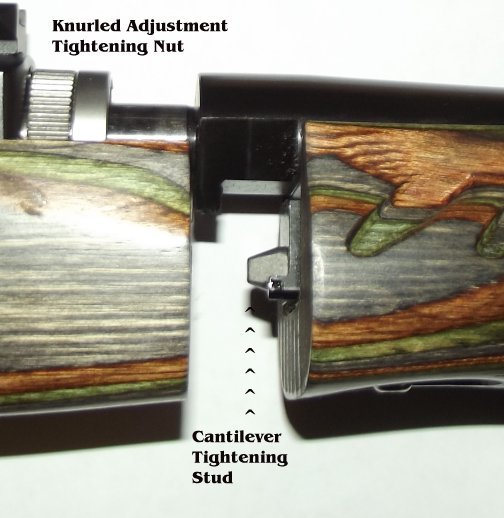

POINT OF IMPACT SHIFT

|

There is still a point-of-impact

shift of up to an inch at 25 yards when the barrel is removed and then

reinstalled. The problem is the tension post/stud on the rear of

the barrel half bears on a

plate 1/2'' or so beneath the barrel - there is always a slightly different

upward

pressure on the barrel in lockup and no way to solve that problem I can see

because the barrel itself is not threaded. This would not be a problem

for the fixed barrel Charger and 10/22. |

|