|

A guide to self reliant living |

||||||||||||

|

6. Kerosene heaters and cookers

12.

Electrical; generators

Miles Stair's SURVIVAL

Miles Stair's

SURVIVAL

|

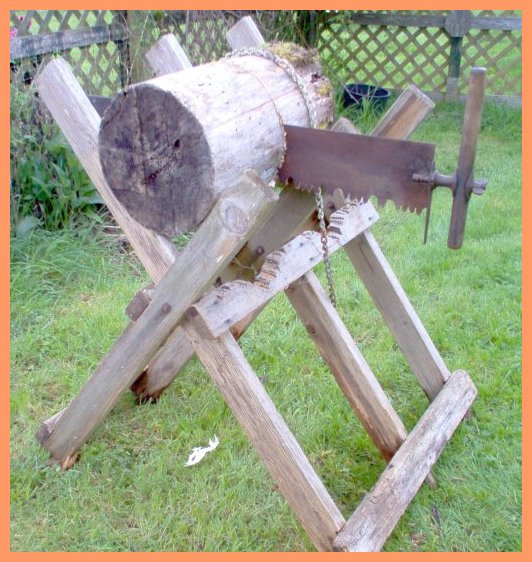

DRYING AND STORING FIREWOOD DRYING FIREWOOD Wood for burning in a wood stove must be "dry" to burn with maximum efficiency. "Dry" means the wood must be aged, so it is not "green," and also not "wet" from rainwater. When a tree is cut down, the wood is "green," or saturated with water through the normal capillary action needed to keep the tree alive. Depending upon the exact tree specie, it can take well over six months of normal storage for the wood to "season" and no longer be "green." If you harvest your firewood in late summer or early fall, you can cheat and speed up the seasoning process. I am assuming you use a stick for measuring* where to cut, so all of the pieces are the same length and therefore will stack reasonably well in a single row. The quickest way to season firewood is to stack it in a single row along a fence, if possible, and slightly lower than the height of the fence. At that point, clear plastic sheeting, 4 mil thickness recommended, can be draped over the fence and the firewood. To keep the plastic tarp from blowing off, place a piece of lead or a smooth rock on the edge of the tarp, roll the tarp over the rock, then tie the tarp beneath the rock with heavy twine. Repeat every 4 feet and at the corners. The smooth folds of the tarp will prevent it from tearing, while the weight of the rock or lead ingot will keep the plastic sheet from blowing away. The plastic sheet need only cover the top of the wood stack and down to a foot or so off the ground. The sun heats the wood, condensation form upward against the plastic sheet, then drains down the side. What you have done is create a miniature greenhouse! The fence keeps the tarp above the wood, and being draped over the fence, it does not touch the wood on that side. The heat of the sun is trapped by the plastic tarp, the wood heats up, and natural condensation forms on the plastic tarp, draining moisture away from the wood beneath it. With this method, it is possible to dry "green" wood into a burnable condition within only 4 to 6 weeks, and it will be ready for use in the winter. The firewood may then be stacked for storage and use as below.

[Update October 21, 2005. I was asked by a reader to amplify the plastic sheet system and the weights to hold it in place. [See middle photo above.] I melt wheelweights, flux with a pea sized piece of beeswax, remove the dross, steel clips, debris, etc, and end up with clean lead, 89% lead, 1% tin, and 10% antimony. I carefully ladle the molten lead into a muffin tin, so each "muffin" is a lead weight shaped like a muffin. Sharp edges around the top are removed with a wood rasp. I then drill a hole near one edge of the lead weight with a 1/4" wood drill, and chamfer both ends of the hole. The weight can then be used in the edges of the plastic sheeting during drying, and to hold down a tarp if the wood is stored outside. I use seine line, which is about 1/16" nylon cordage, cutting a piece about 18" long by burning it with a lighter; cutting nylon cord leads to frazzled ends, but melting it through leaves nice ends that will not fray. That piece of cord is then tied in a circle by folding in half and tying a half hitch at the ends. Poke the end through the hole in the weight, pull it through, and drop the weight through the circle you pulled through the hole. Now the weight is suspended from a short, doubled length of seine line cordage. To keep a tarp in place over a stack of wood, put the end of the cord through a grommet on the tarp, pull through a loop, drop the weight through the loop, repeat at every grommet, and the tarp will then hang tightly down over the wood. If a strong gust of wind hits the tarp it will lift it up, and when the wind dissipates the weights will settle the tarp back down on the stack of wood. If you try to tie a tarp down by the grommets, a strong gust of wind can tear the grommets right out of the tarp! With the weight system, though, the tarp is free to lift, not tear, but not move enough because of the weights to blow off the stack of wood.] * The most common length for stoves is 18 inches. Some stoves will accept 20" long pieces, and fireplaces will usually accept 24" lengths. But you do not want various lengths that must be sorted later before use, so it is best to cut them all to the useful length for your stove.

A "cord" of wood is 4 feet high, 4 feet wide, and 8 feet long, or 128 cubic feet. A stack of 16 inch wood 4 feet high and 8 feet long is 1/3rd of a cord, and is also called a "face cord." It takes three "face cords" to equal a legal cord of wood. Therefore, a stack of 16" pieces of wood stacked 4 feet high and 24 feet along a fence is a whole cord. If loosely stacked, 18" lengths of wood also can add up to 1/3rd of a cord, as the "volume" is deceptive because the wood can be stacked loosely. If you have wood delivered "by the cord," make sure it is stacked up, not just dumped in a pile, or you may well find that your delivery is NOT a whole cord of wood -- what you paid for. Freshly cut green wood is very heavy. If you order wood delivered and it comes in the back of a 3/4th ton pickup, you are NOT getting a whole cord of wood, period. The truck cannot carry that much weight safely (3,000 to 5,000 pounds), nor can it hold the volume of a cord. A standard long pickup bed is 8 feet in length, 5 feet in width, and less than 2 feet in height. That is 80 cubic feet of wood, not the 128 cubic feet in a whole cord. Even if the wood is stacked up higher on the pickup bed, say to an average of 3 feet high, it is still less than a cord, and the weight would have the bed of the pickup right down on the rear axle with the front end almost off the ground - very unsafe driving conditions. [Note: I live in the rain forest of Western Oregon where "green" Douglas fir, spruce and hardwoods are very heavy. East of the Cascade Mountains wet wood such as pine is often lighter and will not overload a 3/4 ton pickup, but the volume issue remains constant.] STORING FIREWOOD Firewood should be stacked off the ground so air can pass beneath it, or the bottom layers will stay wet and moldy. It is relatively simple to lay down long, straight branches, and stack the wood on them -- just be sure the branches (or old 2 x 4's, whatever is available) are parallel to the stack and near the outer sides of each row or rick...in other words, about 15 inches apart. That way the stacks will still be stable. The entire stack of firewood may then be covered with a tarp to keep it dry. Lashing a tarp over a stack of firewood does not work well, as wind will enter somewhere and tear at the tarp. Weights tied to the grommets on the tarp work vastly better. [See above for how to tie on ingots]. COMMERCIAL SALE OF FIREWOOD There are those who have access to woodlots, have the tools and ability to cut and split the wood, and would like a steady source of income from the dry, split firewood during hard times. Some people fill up a pickup bed with the firewood, park at a road junction, put up a hand lettered sign, and wait for someone to drive by who wishes to purchase the wood. That is not an efficient use of time or resources. The best potential source of turnover and quadrupled profit is to shrink wrap in plastic film a small bundle of firewood and sell the bundles to local supermarket stores. Reader Nick suggested the use of pallet or bundle wrap for this purpose, and it would be ideal. "A savvy person could twine and wrap it such that a hank of twine would be left exposed to serve as a handle. Contrary to what some may think, you should NOT wrap the bundle in plastic completely! Unless the wood is kiln- or oven-dried, it will still have moisture in it, even if it has been seasoned on a stack. Wrapping it tightly will retain that moisture, it will condense in the plastic and cause the wood to rot. Simply wrap the bundle end-to-end, and let the ends remain open to allow the wood to breathe." One source of the plastic wrap is Uline. www.uline.com/Class_03.asp?dup=Stretch+Wrap .

|

1. Food |

2. Manna Meals |

3. Water |

4.

Sanitation | 5. Medical, health

|

| 6. Kerosene heaters and cookers | 7. Lighting | 8. Wood cooking and heating | | 9. Communications | 10. Essential Tools | 11. Home built items | | 12. Electrical; generators and power | 13. War preparedness | 14. Gardening |

RELATED

LINKS:

|

|

||||||||||