|

A guide to self reliant living |

|||||||||

|

6. Kerosene heaters and cookers 12.

Electrical; generators

Miles Stair's SURVIVAL

Miles Stair's

SURVIVAL |

USING CROSSCUT SAWS FOR CUTTING FIREWOOD

When using a crosscut saw, it is more imperative than ever not to cut into dirt and dull the blade. Muscle power is what makes these saws work, sharp saws cut vastly easier, and crosscut saw blades cannot be inexpensively purchased as can a replacement saw chain.

[Update: According to an e-mail I received in January, 2007 from Eric Pfeiffer, Business Development Manager, Simonds International, "Yours is the oldest sample of a Simonds saw that I have come across." The patent dates are May 5, 1874, May 17, 1874, Nov. 9, 1875, Jan. 16, 1877, March 6, 1877, and the saw is clearly marked THE SIMONDS SAW, PORTLAND, OREGON. This saw has been in my family for a long time!] USE A SAWBUCK TO MAKE CUTTING EASIER

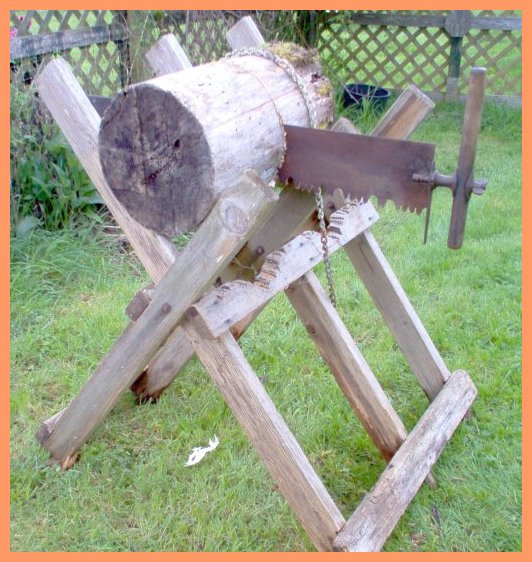

A sawbuck makes sawing firewood with a crosscut vastly easier. The sawbuck elevates the log to convenient sawing height, off dirt, and the log can be cleaned where the cut is to be made. I made this sawbuck years ago from 2 x 4's. Each half is virtually identical. Offset 1", the halves are held together with three hinge bolts with large washers, one per upright in exactly the same place, as visible in the photo on the right. I made the sawbuck to fit inside a garden cart for easy transportation, so there is nothing sacred about the precise measurements. It is 35" wide, the distance between the uprights is 13", the height of one side is 47" and the other side 53", and the height to the hinge bolts is 30 1/2". It is 34" wide at the base when opened because I beveled the cross brace at a 45 degree angle where the uprights hit the top cross brace. This allows the sawbuck to be folded flat for easy transportation to the site of the felled tree...vastly easier than taking the tree to the sawbuck! Note the twisted chain in the center photograph. This chain is pulled tightly over the log and held in place with a short rubber snubber: The twisted chain bites into the wood and keeps the log from rolling or moving while being sawn. I made this sawbuck at least 25 years ago, it's been well used (that is obvious), but it still works just fine! Full size editions of the photos above are available in the Photo Index under "Essential Tools," or by clicking on the photos themselves. The log being cut is a short one. There are always sections like this left over...too long for the stove and too short for convenient stacking when cut, so this makes an ideal demonstration. Also, it was handy when the sun was shining and I could take some photos. When the log is cut down to the point shown, the log begins to pinch the blade. At that point, the log is turned over, cinched down with the chain, and the remaining cut made without binding the saw blade. Not shown is the always needed bottle of kerosene. When the saw starts to pull hard, it is lubricated with a splash of kerosene. The kerosene also cuts pitch, making the saw vastly easier to use. When using the sawbuck with a crosscut saw, the short section can be facing the front, as shown above. If using a chainsaw, cut from the back side, with the higher side facing you, and the tie down chain is MANDATORY for use with a chainsaw. Much longer limbs, small trees, etc, can be cut with the sawbuck then shown in the illustration above. I have cut firewood with a chainsaw from trees over 10 feet long with this sawbuck. Obviously the wood to be cut needs to be centered on the sawbuck, and it is very nice indeed if one end of the stack of wood to be cut is even. Then a 16" (or whatever you prefer) section is cut off one side, then the other end, then back to the other side, to keep the weight balanced on the sawbuck. The cutting goes fast with a chain saw! Using a two man saw is entirely different than using a crosscut saw by yourself. Each person must only pull, not push! You pull the saw across the log, then on the backstroke just keep your hand on the handle to prevent the saw blade from wiggling or vibrating - don't push on the saw - your partner is doing the pulling. It is usual for beginning sawyers to "ride" or push the blade away from them, thus binding or even bending your precious crosscut saw. They need to be "trained" not to "ride the saw," just pull and then let you pull. If you are going to use a two man saw with a beginner, first fill a pocket with pebbles. Every time they push on the blade and bind it, throw a small rock at them. After awhile even the most dense of partners will learn to simply guide the saw blade as it moves away from them and stop "riding the saw" when it's your turn to pull.

Sharpening the large teeth on cross cut saws means having the tools available. The teeth must be sharpened at the correct angle, the "set" of the teeth must be precise and the height of the teeth and rakers must be uniform. Teeth too high or set too wide will bind in the kerf. Dull teeth makes sawing extremely difficult. These tools can sometimes be found in "junque" shops or antique shops and are also available new from the Crosscut Saw Company Click on the photos to enlarge. File and set gauges can also be found inexpensively on eBay...search under "crosscut saw." Crosscut Saw Company sells used/antique saws as well as new saws. Then you need instructions on how to use those tools, as that knowledge base has evaporated with the demise of the older loggers. The instructions for sharpening are here. The US Forest Service manual for using a crosscut saw is here. Cutting firewood with a crosscut saw is work, but it can be done. Best of all, it is silent and does not require any fuel - which might be hard to come by in the future. You can cut your winter firewood without attracting any attention. Chainsaws can be heard a mile away! When you are finished sawing with a crosscut saw, immediately spray it with kerosene and then wipe it clean with a wire brush - including the teeth! That removes rust-causing wood chips and protects the blade until the next time you need to use it. Then carry the saw carefully to where you can store it out of the weather...hang it up from one end, don't lay it down on the teeth or stand it on one end where it can bend and/or take a "set." For travel, it is possible to cut a section of 1/2" vinyl garden hose down the middle. That split vinyl hose can be slipped over the teeth of the saw and held in place with large rubber bands cut from an inner tube, and the teeth won't get dull while the saw is laying on its side in a pickup bed. The US Forest Service manual for using a crosscut saw is here. Missing parts for crosscut saws (and entire saws) can be found from the Crosscut Saw Company. RELATED LINKS:

|

|

|||||||