|

|

||||

|

6. Kerosene heaters and cookers 12.

Electrical; generators Miles Stair's SURVIVAL Miles Stair's SURVIVAL

|

SURVIVAL MEAT PRESERVING - PART 3, BUILDING A SMOKEHOUSE

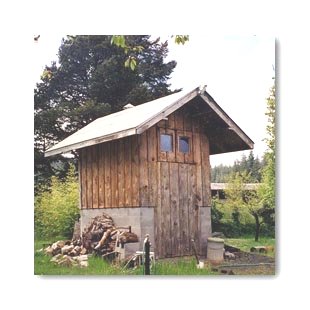

For those of you who want to make dried or smoke cured meats using an easier method than described in Part 2 of Survival Meat Preserving, you must prepare a smokehouse. You can build a smokehouse of cinder block or use an old refrigerator, then construct a separate, underground (or lower) fire pit. The finished smoke house is quite versatile and will enable you to smoke hams and bacon as well as drying meats. They require far less wood than outdoor drying racks, and thus take less of your time and energy to use. While a small refrigerator would seem too small to dry much meat at one time, it can be operated 24 hours a day (No carrying in the racks at night!) and thus can dry meat in about 1/3 rd the time required for outdoor drying. While the use of a smokehouse inhibits sun drying, only slightly warmed, dry air from a very slow hardwood (fruit wood is best) fire will effectively dry the meat properly. And a smokehouse can be used in the winter when outdoor drying racks are not feasible. It is easy to build up too much heat and ruin jerky. But it is possible to generate enough heat to cook hams and bear meat, should that be desired during the traditional fall and winter season for that activity.

The inside arrangements of a smokehouse can be as varied as you wish them to be. Back before electricity - and therefore freezers - smokehouses were large, with hooks in the ceiling to suspend hams and slabs of bacon, two feet or so lower would be strong, removable, thin metal rods to pierce strips of jerky so it could hang vertically and dry, and below that racks on which to dry things that did not hang well. These days, many people in the country use an old discarded refrigerator or freezer to make into a small smokehouse. To prepare an old refrigerator for drying, all of the rubber gaskets, plastic molding inside, and the motor and compressor must be removed. Do not advertise your removal of the compressor, or a pony tailed, sandal wearing EPA inspector will be your constant companion for years. Older models had steel walls, but the modern types have a lot of plastic to remove. Older 10 to 12 cubic foot models are about the right size, and should be available in abundance after the revolution. If the inside walls must be removed (and the inside of the door), then sheet metal must replace it. The bottom and side near the top of the refer must be cut to accept the intake and exhaust pipes, respectively. Three or four inch copper or masonry pipe can be used for the exhaust, but the entrance should be a brick or masonry pipe of 4 to 6 inch diameter. Furnace cement can be used to seal the intake and exhaust pipes. As the door will not seal properly with the rubber gasket removed, the restricted exhaust will build up a positive interior pressure, and force smoke and heat out the door edges. Once the refer is ready, it should be anchored in place with the door facing south, if at all possible. A space can be left at the top for hanging hams or jerky. The racks should be spaced on the inside by using bricks for support, and the bricks can be easily moved to regulate the spacing of the racks. The bricks then retain heat at night, and you could let the fire die out and get some needed sleep. A meat thermometer should be inserted through a hole drilled in the door and anchored in place with furnace cement, to give you a clue as to the internal operating temperature, usually 100 to 130 F (low for jerky, higher for thicker hams and slabs of bacon).

The firebox should be constructed of firebrick or concrete, with a small (2") intake vent and the masonry pipe to the refer carefully sealed in place. The firebox should be constructed in a trench several feet underground, if possible, and at least three feet away from the smokehouse/refer, with the connecting pipe angled upward slightly for natural convection. The exhaust pipe from the firebox to the smokehouse can be installed near the top of the back side of the fire box, so it can be cleaned with a brush from time to time via access through the door to the firebox. And the firebox can be small, only a foot and a half square, as you only need a small fire. If a small hill is not available for this configuration, the firebox can be constructed at ground level and the refer elevated several feet. It is best to build the firebox to the side or back of the smokehouse or refer in order to allow unfettered access to the smokehouse door. When completed, the smokehouse and connecting pipe should be packed carefully with sand and dirt mixed with cement, leaving only a small entrance exposed for the door for adding more wood. The earth will then act as a heat sink, cooling the smoke and making your life much easier in controlling the coolness of the smoke. By using cement in the dirt mixture covering the firebox and exhaust pipe, and having the pipes exiting the side of the firebox and smokehouse, moisture infiltration from rain is kept to a minimum. The intake vent for the firebox should have some method of draft control, however primitive. One easy solution is to use a section of two inch galvanized pipe threaded on the end, with a standard screw on cap to fit the threads. The pipe should have four quarter inch slots cut the depth of the threads with a hacksaw (cut in quarter sections), and the threads then cleaned up. Raising or lowering (twisting in or out) the cap regulates the amount of air passing through the slots, and thus controls the quantity of air reaching the firebox and the heat produced. This pipe intake vent need not be connected to the door: in fact, it is easier to cement it into the firebox separately. Then a door can be made of fairly heavy gauge steel and can be fitted to close tightly. If desired, the door can be opened during the day to allow the sun to reach the meat (hence the southern exposure), and closed at night to retain heat and exclude moisture, but care must be taken to prevent flies from touching the meat if the door is open. A small fire is a must! A throttled down larger fire puts out too much creosote, so use a small fire (occasionally) a little hotter to control that problem, and the heat sink effect will provide residual heat when the fire dies out. If used for smoking meats (and thus cooking them), the door to the refer/smokehouse is closed, the temperature held to around 130 F, and of course the hams or sections of meat should be deboned and packed with salt (or sugar) prior to smoke curing. Excess salt (or sugar) is removed prior to final storage, and the end result is properly salt or sugar cured hams, bacon, whatever, that can be stored for later use without the need for electricity.

|

1. Food |

2. Manna Meals |

3. Water |

4.

Sanitation | 5. Medical, health

|

| 6. Kerosene heaters and cookers | 7. Lighting | 8. Wood cooking and heating | | 9. Communications | 10. Essential Tools | 11. Home built items | | 12. Electrical; generators and power | 13. War preparedness | 14. Gardening | |

|

||