|

A guide to self reliant living |

||||

|

6. Kerosene heaters and cookers 12.

Electrical; generators

Miles Stair's SURVIVAL

Miles Stair's

SURVIVAL |

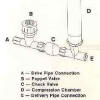

RAM PUMPSHow does one get water to a higher elevation without carrying it or using a hand pump? If there is a running stream or spring that flows briskly, it is possible. The answer is found in a Hydro Ram pump. A ram pump requires hydraulic pressure to operate the pump (Not electricity!), so a drop or "head" is mandatory to make the pump work. The ram pump then uses the energy generated by the weight of the water to continuously pump a fraction of it uphill up to 10 times the "head" or fall feeding the pump. When the ram pump's poppet valve (the only moving part) is open, water flows downhill through the supply pipe to the pump and escapes out the open valve. That is waste water, and is utilized to generate the kinetic energy required to pump some of the water up the delivery pipe. As the water gains velocity in the supply, or drive pipe, it causes the poppet to snap shut, which causes hydraulic pressure to peak immediately (a "water hammer" effect), which forces some water through a check valve, and into the delivery pipe. This cycle repeats itself about once a second. For those who have a mountain stream which could provide water to a cabin at a higher elevation, it is possible to add a reverse osmosis water purifier to the ram pump, so creek water can be delivered to a holding tank in pure condition. The ideal situation is to use a ram pump in combination with a large storage tank situated at least 30 feet higher than the home. As the ram pump operates continuously, a smaller ram pump can fill a storage tank that can be drawn down during the day, for example. And assuming a pressure factor of 0.43 per foot of drop*, an elevation of 30 feet would deliver water to the ground at 13 PSI. That is certainly good enough to deliver water in quantity for most uses.

Ram pumps have been around for a least a century. The older, bell shaped ram pumps manufactured by Skookum were made of cast steel, and lasted forever. They also cost a small fortune. Now there is an alternative, made from PVC, which will handle falls of 15 feet and lifts to 150 feet reliably. And, they are relatively inexpensive. If the fall is over 15 feet and the lift required is over 150 feet, then a more expensive steel ram pump is indicated. The installation of a ram pump is not overly complicated, but it does require some study. You have to know how far downhill you will have to "pipe" the water before you get a sufficient "drop" or "fall" to operate the pump, how high and how far the water needs to be pumped, and how much water will be needed per 24 hour period. Once those basic factors are determined, you will then need to study the catalogue from Fleming Hydro-Ram Pumps very carefully to choose exactly which size pump will work for your individual situation.

For more information on ram pumps, contact http://www.theramcompany.com/do4u.html Fleming Hydro Ram Pumps PO Box 698 Amherst, VA 24521 phone: 804-277-8511 OPERATION

OF A HYDRO-RAM

~~~~~~~~~~~~~~~~~~~

|

1. Food |

2. Manna Meals |

3. Water |

4.

Sanitation | 5. Medical, health

|

| 6. Kerosene heaters and cookers | 7. Lighting | 8. Wood cooking and heating | | 9. Communications | 10. Essential Tools | 11. Home built items | | 12. Electrical; generators and power | 13. War preparedness | 14. Gardening | |

|

||