|

|

|||||||||

|

Tuning the Ruger Charger Pistol Bug-out-Bag (BOB) Tips and Tricks Bug-out-Bag (BOB) Tips and Tricks 6. Kerosene heaters and cookers 12.

Electrical; generators Miles Stair's SURVIVAL Miles Stair's SURVIVAL

|

[OK, now you don't have to make your own all-brass .410 hulls. Midway has 2 1/2" hulls already made! But I will not delete the information below because you may have to make your own in the future.] Magtech Shotshell Hulls 410 Bore 2-1/2" Brass Box of 25 See below for more information from a reader of this page. Annealing. See

also

Survival Reloading and

Using Lyman 310 Tong Tools for Reloading Long term reloading of .410's means using all-brass cases. That requires more knowledge and skill, but the brass cases will last virtually forever. Extremely sturdy brass cases can be made from .303 British cases, .444 Marlin brass, or for full length 3" cases, 9.3 x 74R brass can be used. First the empty cases should be annealed, then fireformed with 8.0 grains of Herco and a case full of Cream of Wheat (load single shot, straight up, then fire). The Cream of Wheat will blow the case walls straight, including the shoulder and neck, resulting in a straight sided all brass case. For reference, the base diameter of factory .410's is 0.469", and the rim diameter is 0.524". .444 Marlin cases are straight walled and can be used as .410 brass without the need for fireforming, but have the penalty of a 2.162" case length. The base diameter of the .444 Marlin is 0.469", whereas the .303 British has a base diameter of 0.458". The rim diameter is smaller with the .444 Marlin - 0.514" instead of the 0530" rim diameter of the .303 British - so it is theoretically possible that a really loose extractor might not catch the rim. The 9.3 x 74R European brass has a base diameter of 0.465", a rim diameter of 0.524, and an overall length of 3.47". The rim thickness (headspace) of the 9.3 x 74R, however, can be a tight fit in minimum .410 bore shotgun chambers, and may need to be thinned before use. Obviously we're only talking a few hundreds or thousands of an inch differences here, but it is a complication not taken with abandon. Let me digress a little. By now you are wondering why the cases mentioned above all have essentially the same base diameter. The reason is the cost of the draw dies when the cases were designed and originally manufactured. In 1869, when the .44 S & W American was designed, draw dies for making brass were very expensive, so they were used for other cartridges as the need arose. In 1870, Smith & Wesson developed the .44 Russian - so manufacturers used the same draw dies. When development work was underway in the early 1890's on the .303 British and .30-40 Krag, again those same draw dies were used to form the longer rifle cases. Then in 1907 came the .44 Special, etc. In the finishing process, of course, rims of different diameter and thickness could turned, so the .30-40 Krag rim is 0.540" in diameter, as opposed to the 0.530" rim diameter on the .303 British. Shotshell cases were originally drawn brass, not paper or plastic. The base diameter of .410 shotshells is 0.469" and the rim diameter 0.524"...not surprising that brass cases will work, as they were made with essentially the same draw dies! For single shot shotguns, an all-brass case made by fireforming .303 British brass seldom requires resizing, needing only a new primer before reloading. The resulting case is 2.25" in overall length. As shotshell length is measured as fired, a 2 " .410 case actually measures 2 1/4" when loaded....the same as the all brass shell made from a .303 British case! Wonder of wonders. Like it was meant to be. Actually, it was, as you will see. Occasional sizing may be needed, and can be performed using a .44 Special size die and a .303 British shell holder. Heck, I knew a geezer who sized only the top 5/8" or so of the brass with an old .30-40 Krag sizer die! He had an oversize chamber, so it made sense to use the seater die instead of the actual size die, as the brass was worked less and lasted longer. With strong, thick walled rifle cases designed for 38,000 PSI or more, only the top third of the case expands at the 12,000 to 14,000 PSI working pressures of .410 shotgun loads. Tubular magazine shotguns like the Mossberg HS410 and Winchester 9410 need a slight crimp in the case mouth and mild sizing for reliable feeding, which can easily be done with a .44 Special/Magnum crimp die (or .444 Marlin) with the bullet seater insert removed. Shotgun primers are actually pistol primers minus the anvil, the rest of the shotgun primer assembly actually being a Berdan primer-type holder. In the 1950's and 60's, it was common practice for shotgun reloaders to simply replace the primer in the assembly, and Cascade (CCI) made primers without anvils just for that purpose - I still have some - but it was tedious work. When loading brass cases for use in the .410 bore shotgun, pistol primers should be used. It all has to do with the pressure generated by the loads and the designed impact of the firing pin: pistol primers are designed to ignite with only 6 to 9 pounds of impact, and resist pressures only half that of rifle primers. A powder charge of 8.0 grains of Herco under to 5/8 ounce of shot will work well. Card wads are needed over the powder and the shot column, and felt wads are needed over the powder wad. These wads can be cut from thick felt or solid cardstock using a home made punch. A 300 H & H case can be sized in a .44 Special seater die deep enough to create about 3/8" of straight wall on the side of the case. Cut the case at the top of the straight section, then again just above the solid web at the base of the case. Sharpen the outside of the case mouth with a deburring tool, leaving the inside edge straight. Card stock is then placed on a relatively soft but flat surface, like a piece of truck inner tube on a kitchen cutting board, to protect the cutting edge of the home made wad cutter. Use a rubber hammer on the top of the card cutter, and disks of the correct diameter will be cut perfectly. The card wads should be left "dry," but felt undershot wads should be lubricated to reduce leading in the barrel. There are nice commercial products available for this, or you can soak the felt wads in a 50-50 mix of melted beeswax and Vaseline, then let them cool and dry on paper. Wad pressure is a controversial subject. Of more importance is seating resistance, where the top wad is sealed firmly enough to enhance pressure buildup before releasing. The old way, when all brass cases were the norm, was to put 8 to 10 drops of waterglass (also called "egg keep") on the top wad. In an emergency, use what you have, such as Elmer s glue, and clean the barrel more often. Obviously, the height of the load within an all brass case depends upon the thickness of the felt wads used, but the actual height doesn t matter much, really, as long as the top wad is securely sealed. This is a total departure from loading recommendations for plastic shotshell cases, but all brass cases don t need internal support for stability of the top folding or roll crimp, as there isn t one. As long as you weigh (or measure) the powder charge and shot charge, the thickness of the felt wads is not that critical. Of course you can experiment and add of subtract felt wads to reach the top of the case if you want too, just as it is possible to cut plastic strips (similar in thickness to gallon milk jugs or bleach bottles) to surround the shot column inside the case to reduce lead shot scrubbing against the barrel. Making shot is not hard: making it round and uniform is very tricky. Drop melted lead through a sieve into water and you have made shot. Teardrop shapes, odd sizes, but it is shot. Dropped from a considerable height through a chimney (or stove pipe) into water makes the shot more uniform in diameter, but in emergency situations may not be worth the trouble. Patterns with home made shot are usually twice as large as with nice, round commercial shot, but it works! Simulated "buckshot" can even be made using .225" to .309" light weight cast bullets or round balls by using split shot sinker molds. The resulting "buckshot" does not have a great pattern, but does have greater penetration than smaller shot. When loading, the "buckshot" column should be buffered with Cream of Wheat filler or coarsely ground wheat to reduce leading and provide feed for more birds. For a really devastating load, use split shot crimped over strong monofilament, so the buckshot is essentially tied together with a two inch or so separation.

Of course I recommend having reloading tools and bullet molds for all of your rifle and handgun cartridges. You may not be able to get jacketed bullets, but if you have the primers, powder and a bullet mold, your rifle, pistol, revolver and shotgun can still work in hard times. My booklet, Survival Reloading, has reloading tables for virtually every cartridge you might ever encounter, for both cast and jacketed bullets. Order here. ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ COMMENTS FROM A READER! Brass shells come in two

basic flavors: ~~~~~~~~~~~~~~` QUESTIONS FROM READERS OF THIS PAGE QUESTION: DEANE. I HAVE QUESTION ABOUT THE ANNEALING PROCESS. PRECISELY HOW DO YOU ACCOMPLISH THAT? ARE YOU SIMPLY IMMERSING THE DE-CAPPED .303 CASES IN MOLTEN LEAD AND THEN QUENCHING THEM WITH COLD WATER? HOW MUCH OF THE CASE DO YOU HEAT? I CAN RECALL YEARS AGO IN MONTANA, WE USED TO STAND OUR CASES IN A CAKE PAN OF WATER AND HEAT THE CASE MOUTHS ONE AT A TIME WITH A PROPANE TORCH. WHEN THEY WERE HOT, WE TIPPED THEM OVER. IS THIS BASICALLY WHAT YOU'RE UP TO? ANSWER: I anneal all my brass in hot lead. Wheelweight alloy (89 lead, 1 tin, 10 antimony) melts at 619 F. The reason for using lead for annealing is to keep the temperature low enough for proper annealing AND have uniform annealing, and that is simply not possible using the torch method. With the propane torch, you stand the cases upright in a pan of water, heat the shoulder and neck, and when it glows the case is tipped over into the water. The case is heated on one side more than the other, and in falling over into the water, one side is quenched before the other side. I use primed cases, using fired primers, as that forms an airlock that keeps lead from entering the case. Then I dip the case mouth (and about a half inch below the shoulder) down into the molten lead for about a count of two, pull it up out of the lead, tap on the side of the case to remove any bits of lead (if the lead is really sticking, the case isn't annealed!), then drop it mouth down (straight) into a 3 pound coffee can mostly full of ice water. I have another can with ice cubes, and every 10 rounds or so I add a few ice cubes to keep the water cool. I don't use gloves, as if the case head I'm holding got hot enough to require gloves, I would be annealing the case head and primer pocket too -- bad news. Usually I don't tell people about this method because they may not be mentally organized. Water and molten lead do not mix, and I worry about the liability angle I don t assume any liability because people can t follow directions properly. Being left handed, I have the cases on the right side, the lead in the middle, and the ice water on the left. The cases go only one direction -- to the left -- and I use only one hand. Because it only takes a few seconds per case, I can anneal hundreds of cases in an hour with this method. Over three decades ago I experimented with various methods of annealing brass, including the torch method. The reason was that I was that I was making brass as a commercial reloader specializing in obsolete and wildcat cartridges. I needed the cases to last, and fireforming had to be easy and reliable. I made a lot of 7 mm Weatherby out of anything belted, from 375 H & H on down to 300 Win Mag, and that entailed actually reducing the body diameter/taper to that of the 300 H & H case, trimming to 2.555", inside neck reaming, then fireforming with 15 grains of Herco and a case of Cream of Wheat. Same thing with 7 mm Ackley Improved and the various Gibbs cartridges made from 30-06 brass (with 10 or 12 grains of Herco depending upon case volume) -- fireforming was a must. In my trails, annealing in lead gave the best results. But I know of one dude who dropped an ice cube into the lead pot and got himself (and everything close) covered with a thin film of hot lead, so I hesitate to tell just anyone about this method. ANNEAL AT YOUR OWN RISK! -------------------- QUESTION: Dave: Being a bit lazy, I was looking for an easier shell to form that the 303. Taking a look at the 405 Win, I think most of the work is already done. ANSWER: I looked at the .405 Win, and Hornady does make it again, but I don't think it would work without some extra work. The rim diameter of the .405 Win is 0.543", whereas the rim diameter of .410's is 0.524". As you know, the rim is countersunk into the rear face of the chamber, and .303 Br with a rim diameter of 0.530" is about maximum to fit the rim recess in my three .410's...ergo, the rims of the .405 Win would have to be filed down. True, the .405 Win has a case length of 2.58", but .410, 2 1/2" shells are only 2.25 OAL, only being .2 1/2" when the crimp is opened. So the extra length doesn't gain much. Nice try! Good idea, but .444 Marlin cases are probably better if you don't want to fireform. QUESTION: Dave: My point being this Brass would load 410 x 2.5 virgin right out of the box. Now my question is, if I decided to size it and load it with 45 Win bullets, as the pistol is riffled, what charge would you recommend. For that matter I could load it like a shot shell, that just has a heavier slug, wads and all? ANSWER: Won't work right out of the box because of the rim diameter. But if loaded with 0.454" bullets of 250 grain weight, a load of 12.5 grains of Herco would be about maximum....410's are NOT strong actions. QUESTION: Dave: I found your Herco burned at ~59% Bullseye. If I wanted to load it as a metallic cartridge, would I go with a slower burn rate or a faster one? ANSWER: On a burning rate chart where Bullseye is 1 and H-4831 is 100, Herco is 15. It burns in about 9 inches, is a very bulky powder, so it is about ideal when loading a huge capacity case with a small amount of powder. 2400 is too slow for your 9" barrel (burning rate about 22), and Unique is too dense, burns too hot (temperature), and burns too fast (10 on the burning rate chart). Bullseye is way to fast burning for anything but plinker loads. So we're back to Herco as being the right burning rate, bulky to help fill the case, and has a very predictable pressure curve, so I would stick with Herco and simply load a .45 Colt load but in the longer case. A little Dacron fluff (steal from a pillow) will hold the powder against the primer as well as cushion the base of the soft lead, plain base bullet. Right...NOT a jacketed bullet, but a cast bullet, as the pressure limitation imposed by the action itself mitigates for cast bullets over jacketed bullets with full loads. QUESTION: Dave: Of course I could just be committing suicide too.. hehe. ANSWER: Nah. Just take it easy and use loads designed for OLD .45 Colt revolvers, and you should be OK. There are loads on the Internet for .454 Magnums based on the .45 Colt solid head case, but the revolvers that fire them weigh more than a .410 shotgun and have twice as much steel around the chamber area as a .410 shotgun. Those magnum loads generate up to 54,000 PSI, whereas the .410 shotgun is designed for about 14,000 PSI chamber pressures. There is no way you can duplicate a .454 Magnum load in a "normal" .410 shotgun without going into orbit. QUESTION: From Richard. Thank you so much for your very informative web Site. I found it a pleasure to read I have a New England Firearms .410/.45 Colt. It is a rifled 3 slugger. I have successfully made some nice .45 Colt Magnum rounds. But I am WANTING MORE ..HEHEH I am having trouble finding 9.3x74R cases so I can use a full 3 or at least 2.75 of the chamber I know from your report that a .444 Marlin and the .303 Brit will work, but those are still a bit short Any other ideas??? Or maybe suppliers of the 9.3 s Also can the 9.3 s cases withstand the pressures that I may be putting on it My round of choice is a 240 JHP if that helps, but may be willing to try something in the 300 gr range if I can find some good hard cast lead ANSWER: You have a top break, single shot action designed in the 1890's as a maritime 10 gauge line throwing gun. With modern steel and heat treating techniques, it will take pressures of 50,000 PSI, however, the pressures should be reasonably limited to about 42 to 45,000 PSI to keep the action from getting loose. The 9.3 x 74R case was designed to approximate 375 H&H flanged ballistics in a rimmed case for drillings, so that brass can take MORE pressure than your rifle can handle! But that isn't the problem. You want, I think, to duplicate .444 Marlin ballistics in your .410/45 Colt. The best powders for the .454" expansion ratio of your bore are in the medium burning rates, NOT the bulky slower burning rate powders, so you most likely would be using 4198, 4320 or 4895 (heaviest bullets), and there is more than enough case capacity in a .444 Marlin case to achieve the ballistics you want. The 2.162" length of the case is not a problem for holding enough powder, and the powders mentioned, even being double based, have sufficient deterrent coating to not cause any appreciable chamber erosion, so using the shorter case would not harm your rifle's chamber, and the cases do not need much alteration of the rim to fit the rim recess in your rifle. The 9.3 x 74R rim is both a larger diameter AND thicker (headspace), so it needs more alteration. I'd go with the .444 or .303 cases, in my opinion. Of more significance is the primer pressure limitation. No matter what the load INSIDE the case, a .45 Colt case is designed with a shallower primer pocket for large pistol primers. Those primers only take 6 to 9 lbs of pressure to ignite because the cup is thinner, BUT that thinner cup limits your pressures to well under 50,000 PSI or the firing pin indentation will blow through. The .303 or .444 Marlin cases are designed to accept the deeper large rifle primers, which take 12 to 15 lbs of striking force to ignite, and can handle pressures to at least 60,000 PSI. Given that your rifle will produce enough energy to reliably ignite rifle primers, and you are going to be using rifle powders, I'd be inclined to use the readily available .303 or .444 Marlin cases and STANDARD (not magnum!) large rifle primers. You also have very shallow rifling, and that mitigates AGAINST cast bullets, even hard cast bullets. You also need to consider bullet expansion at the velocities you will be achieving, and that means using 240 to 300 grain bullets with thick jackets designed for upwards of 2,000 FPS, NOT the thin jacketed bullets designed to expand at 1350 to 1500 FPS in the .45 Colt or even the .454 Casull. I really hate to write this, as I'm a cast bullet fan from way back. I use them exclusively in my 1881 .303 Martini (at 2415 FPS!) and even use them in my 7mm Wby Mag. But I've got .004" rifling in those barrels, and you do not have that in the New England SS, so cast bullets would not generally give very good accuracy. Sorry. QUESTION: How do I bell the case mouth, or remove a dent, without having a special belling die? And what is the least expensive way to decap cases? ANSWER: If you have to round out the mouth of bent cases, or perhaps even to slightly bell the case mouth for removing a previous crimp that is not completely blown out on firing, use a .30-06 case. It has a shoulder diameter of 0.441 to 0.447", and a shoulder angle of 17 degrees. Fill the case with melted lead for weight and to add inner strength so the shoulder has enough strength to last for years. Place the case base down on a solid surface, put the belling tool in the case mouth, and rap gently with a light hammer.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ NOTE: Obviously I believe that everyone interested in survival should have reloading and bullet casting equipment and supplies, plus reloading data for every cartridge normally encountered. Keeping your own rifles and handguns working - as well as those of your neighbors - would be an obvious advantage in most any survival scenario. Full power loads are not needed for this purpose. Cast bullets at moderate velocities would be just fine, and far better than nothing at all! See Survival Reloading.

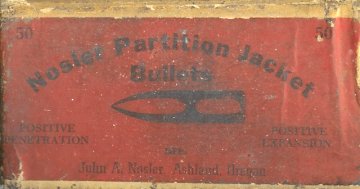

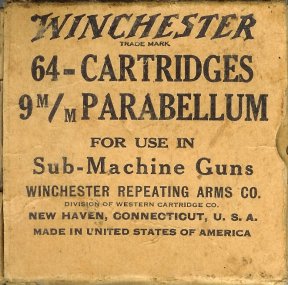

A little nostalgia for long time reloaders. Nosler only produced bullets in Ashland, OR for a few months in the late 1940's before moving to Bend, OR. Winchester made the high pressure 9mm's for submachine guns only for the military 50 years ago. The Barnes bullet box on the right was from one of his first lots of bullets, well over 40 years ago.

"Those who hammer their

guns into plows will plow for those who do

not." |

|

|||||||