|

SITE

INDEX

QUICKENING

NEWS

PREPARATIONS

1.

Food

2.

Manna

Meals

3.

Water

4.

Sanitation

5.

Medical,

health

6.

Kerosene heaters and cookers

7.

Lighting

8. Wood

cooking and heating

9. Communi-cations

10. Essential

Tools

11. Home

built items

12.

Electrical; generators

and power

13. War

preparedness

14.

Gardening

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

HOME

RADIATION

INDEX & JET STREAM

PROPHECY

COMMENTARY

BY MILES

BOOKLETS

BY MILES

GUEST

SUBMISSIONS

PHOTO

INDEX

LINKS

SITE

INDEX

Miles Stair's

SURVIVAL

SHOP

|

|

Cabin Building

Without Nails

Some of the tools

required.

Tools for building a safe,

secure, livable cabin in the woods are still available, it

just takes a little effort to find them. Given the

extreme instability of our so-called "civilization" it may be

necessary in the future to have such an alternative living

space.

More tools and information

on the Shelter page - click here.

And still more tools on the

Tools - Restoration

and Rebuilding page.

And

Tools For Cabin Building

Sharpening crosscut saws.

Crosscut Saw

Manual.

And

How to make sheathes to keep tools sharp.

First, building materials

must be obtained. In my part of the country that means

logs - felling trees.

|

|

A selection of cross cut saws,

from 3 feet long on the left to a 4 foot saw on

the right. The 3 foot saw is good for cutting

notches in logs and cutting firewood sections

from up to 12" diameter logs, while the longer

saws are better for felling and also bucking

larger diameter logs. |

|

|

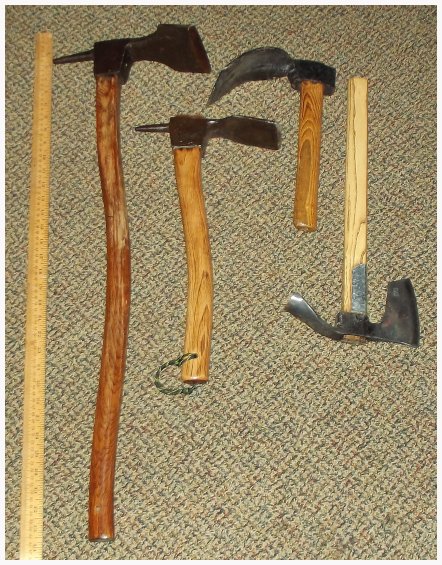

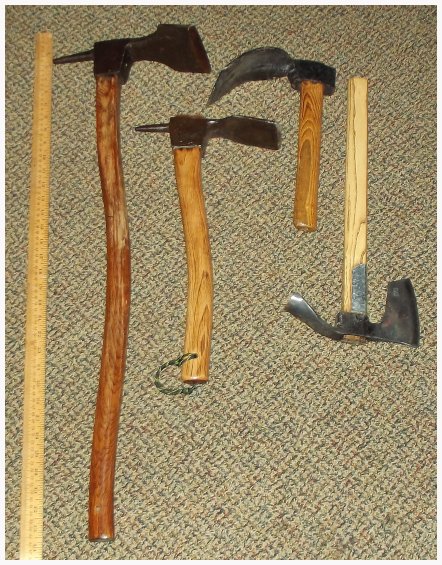

Single bit axe on the left is

good for chopping off limbs, and safer for the

inexperienced to use than the double bit falling

axe on the right. |

And then the logs must

be smoothed and shaped, and if there is time debarked.

Debarking of old growth logs required a ''slick,'' a huge

chisel about 2 feet long with a 4'' wide blade. Second

growth logs usually encountered these days can be debarked

with smaller - but still sturdy - 1 1/2'' or so chisels.

Or large draw knives. The draw knives shown are my

smaller 6 and 8 inch folding handle draw knives. I use

10'' solid handle draw knives for bark removal and rough

shaping.

Shaping logs so they fit

snugly together is done with hand saws, bow saws, broadaxes,

framing hatchets and adze. Broadaxes are scarce and

expensive so other tools are generally used now. The broadaxe

shown below is at least 150 years old.

Adze tools come in a

variety of shape and sizes for cutting and shaping wood for a

specific purpose.

|

The

hand adze shown above has a short 12" handle with a

blade 3 3/4" wide and weighs over 3 pounds. This

tool is excellent for rough cutting the face of a log

to a smooth surface for door sills, window frames and

flooring. The short handle allows working in

tighter places and the weight of the head does the

work. This adze was made for the Italian

military in WW I and is hand forged. I purchased

this adze from Sportsmansguide.com in July, 2015 for

less than $15.00 |

`

|

|

This

lighter adze with an 18'' handle is used to smooth logs

and boards so they fit together better, smoothing logs for

use as window and door casings, plus a whole host of other

cabin building work.

A lighter

adze is easier to swing but does lack the energy needed to

hog off wood quickly. This adze is used to smooth a

finish after the heavier adze above has removed most of

the wood. |

`

|

|

|

|

A bowl adze

is used to cut a hollow in wood to make bowls, plates,

rain gutters, etc. This is a small adze with a 1.6''

curve, a 14 5/8" handle, and the head weighs 14 ounces.

This adze is new, hand forged from high carbon steel by

Ivan Stoev in Bulgaria. Mr. Stoev is a master 'smith

and has many shapes and sizes of axes and adzes listed

(Aug, 2015) on eBay under the store name

thracian-pickers. |

`

|

|

The tool

shown at left is perhaps the perfect "Wildcrafters"

hatchet for building smaller, expedient shelters.

The bearded axe head has a 4 1/2'' edge, the cooper's

adze on the other side has a 1.6'' concave edge can cut

bowls, gutters, notch small logs, etc. The handle is 18

3/4'' long and the total weight is 1 lb 12 oz. This Wildcrafters

hatchet is hand forged by Ivan Stoev in Bulgaria.

It cost less than $60, including very fast delivery, in

July 2015. The eBay store name is

thracian-pickers. |

`

|

The adze

lineup above needs perspective to see the relative sizes

of the various tools. On the left is a traditional

large adze with a 33'' handle and 4 1/2'' face.

The primary use was making logs into planks. These

are dangerous tools and must be used with care!

Hit a knot and the blade can slide off and cut right

into an ankle. Been there, done that. When I was

building a cabin 45 years ago I gave myself a nasty cut

on my left ankle.

The

shorter adze 2nd from left was commonly used in ship

building, the point on the head being used for packing

caulking between boards. This is an excellent tool

for beginners to use for rough shaping of logs on the

interior of cabins.

The

heavy, short handled adze 3rd from left is used for

hogging out wood for making door and window sills,

flattening the ends of floor joists, etc. |

|

I skipped right over the

foundation. Shovels and picks are utilized for that hard

work.

|

|

|

|

|

|

Above, a

heavy hand-forged pick made for the Italian army, most

probably for WW I. It was a little rough from years

of use so I sanded it down with a hand-held belt sander.

In the photos above the handle has been refinished but the

head is not yet finished. This pick was properly

forged with soft iron for the main body and socket.

The pick point is hardened steel and the back and edge of

the blade is hardened steel - a beautiful, time honored

way to forge tools. This large, well-made pick was

purchased in July, 2015 from Sportsmansguide.com for less

than $15.00. |

Fastening logs together or

timber framing is down with dowels put into drilled holes.

|

|

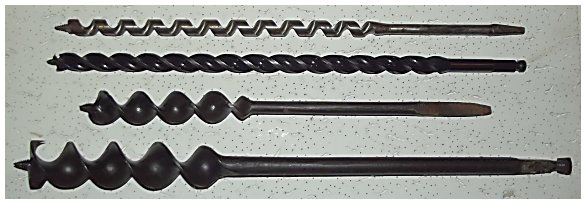

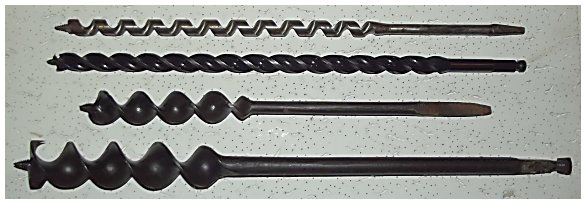

The auger bit above, bottom,

is 26" long. |

|

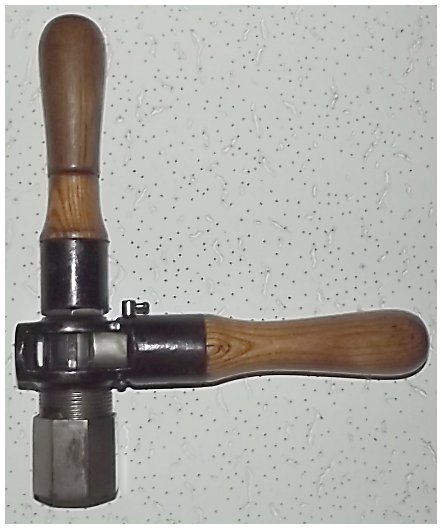

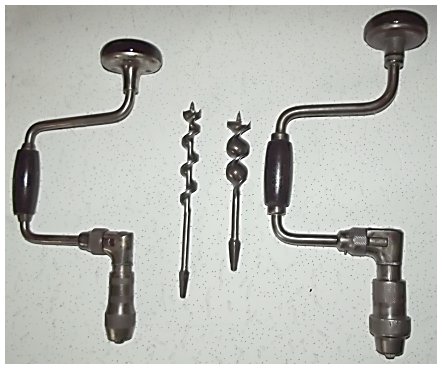

Five types

of auger handles. #1 is a single purpose handle,

hand made in the late 1800's, for the lowest auger on the

right, above. #4 is a James Swann handle, perhaps

the strongest one of all. #5 is a ratchet auger

handle that is very strong - it weighs almost 4 pounds! -

and the left handle can be removed and screwed into the

top for boring holes in corners or tight places. Note that

the top of the handle has a swivel joint and will not tear

out the palm of a hand in use. |

The small

augers at top are 11/16" and 5/8" in diameter. These

are used for boring holes in logs to secure them together

with rebar. The larger augers are for the use of

thick, strong dowels to secure logs together or to the

bottom foundation logs. The small augers are 18"

long - long enough for securing two logs together with

iron rod or rebar so they will not slip. These are

used for logs cut out for window and door frames, for

example. |

`

|

|

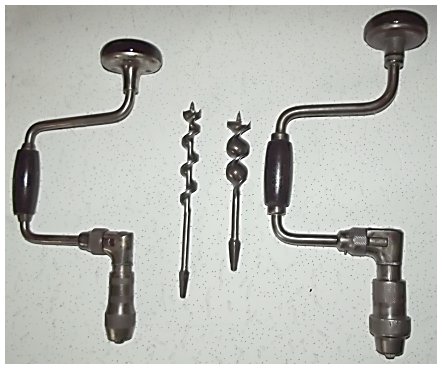

The

standard brace and auger bits can be used for drilling

shallow holes. These are used for window and door

casings, planking, and making furniture using dowels made

with the tools shown below. Note that the auger bit

on the left is a single-flute design for cutting soft wood

that produces large chips when drilling. The auger

bit on the right is a double-flute design for cutting

hardwoods; the double-flute is stronger yet can handle the

smaller chips generated when drilling hardwood. |

And then the dowels are

made....

|

|

Smaller draw knives

are used to shape logs, remove bark when thin, and when

needed to taper the end of poles and wood to be made into

dowels. Folding handle draw knives are especially

handy as when the handles are folded in they protect the

cutting edge of the blade. And they can be safely

and easily carried (see

here). |

`

|

|

Spokeshaves

are used to roughly shape a piece of hardwood so it can be

finished into a dowel. The spokeshaves shown at left

have dual cutters, one cutter being concave to produce

smoother round cuts. |

|

|

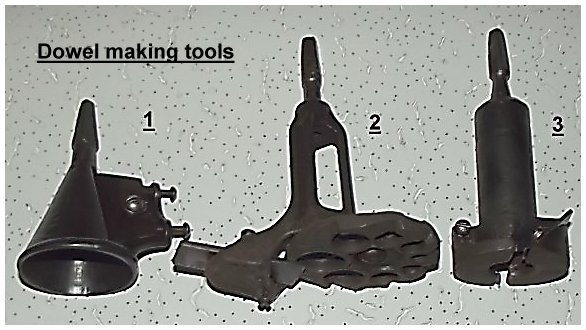

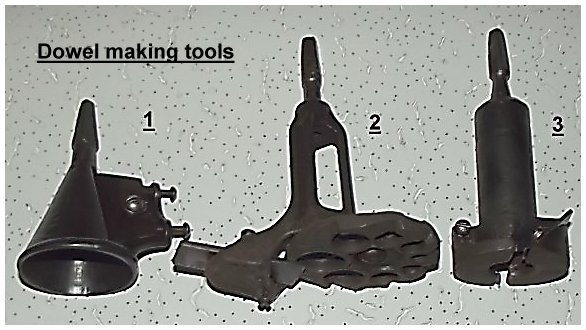

#1 is a dowel

pointer. It tapers the end of a piece of wood so it

can enter the dowel maker. #2 is a dowel maker,

adjustable from 1/4" to 1", and can cut dowels up to 4"

long. #3 is for cutting a flat face on wood at the

end of a 7/8" or 1" dowel for making legs for benches,

tables, etc. These old tools can often be found in

good condition on eBay. |

Then the dowels are driven

into the holes.

|

"Single jacks" are heavy

one-handed hammers.

Right to left: 2 1/2 lb, 3 lb, and an 8 pounder. The 8

pound is tough to use one handed (it can be done), but the handle

is long enough for two handed use when needed. The most

useful single jack for driving dowels is the 2 1/2 pounder on the

right. |

Finally, a froe for making

shakes for the roof...

|

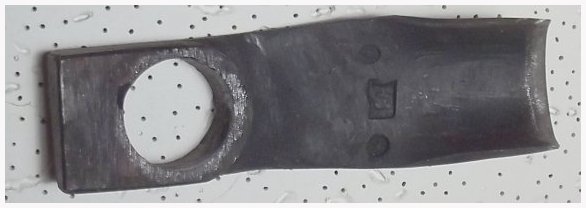

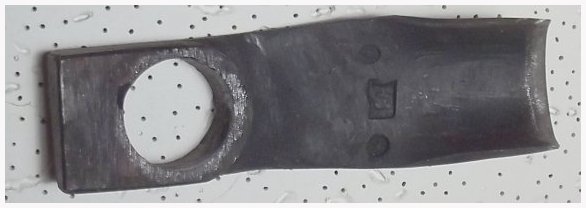

A froe is

for making cedar shakes from "bolts" of cedar or other

wood that splits straight. The shakes can then

be used for roofing. This froe blade is 18" long and

was made in the early 1930's from a truck leaf spring by a

blacksmith in Langlois, OR, in the early 1930's. The

shakes were drilled and wired in place. |

|

The bench below

was made in a half hour. It is crude but it works.

With more time the legs could have been made from dowels and

the seat made nice and smooth, even slightly concave to feel

better when sitting down.

`

RELATED PAGES >

SHELTER

Cabin Building

Without Nails

CARPENTRY TOOLS FOR REPAIR AND CONSTRUCTION

Tools - Restoration

and Rebuilding

How to make sheathes to keep tools sharp.

|

|

|