|

SITE

INDEX

QUICKENING

NEWS

PREPARATIONS

1.

Food

2.

Manna

Meals

3.

Water

4.

Sanitation

5.

Medical,

health

6.

Kerosene heaters and cookers

7.

Lighting

8. Wood

cooking and heating

9. Communi-cations

10. Essential

Tools

11. Home

built items

12.

Electrical; generators

and power

13. War

preparedness

14.

Gardening

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

HOME

RADIATION

INDEX & JET STREAM

PROPHECY

COMMENTARY

BY MILES

BOOKLETS

BY MILES

GUEST

SUBMISSIONS

PHOTO

INDEX

LINKS

SITE

INDEX

Miles Stair's

SURVIVAL

SHOP

|

|

Woodworking Tools

For Cabin Building, etc.

See also:

Tools -

Restoration and Rebuilding

Tools For Cabin Building

WOOD

CUTTING AND SPLITTING TOOLS

How to make sheathes to keep tools sharp.

The photos below show

tools that can be used to make about anything from wood, right

up to building cabins and homes. Many of these tools

were purchased on eBay in relatively good condition, then

refinished. To keep the tools in top shape, sharp

and ready to use, I made sheaths for many of them using old

Levi pants material. The tools are old and rebuilt so

they can last another century - the ultimate recycling.

|

|

|

|

Short, small

adze used for notching logs for cabin building, in corners

and ends where a large adze will not fit. |

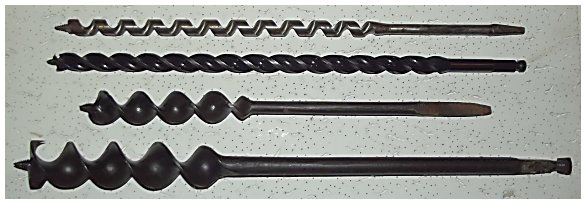

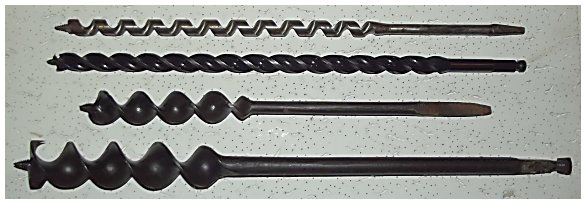

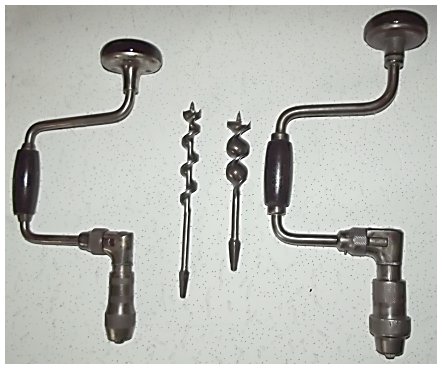

For

post-and-beam construction, augers are mandatory to make

the holes necessary for pegs. The selection shown above is

typical of those available on eBay. #3 is very

versatile for smaller auger bits while #4 is the strongest

type available. |

`

|

|

|

|

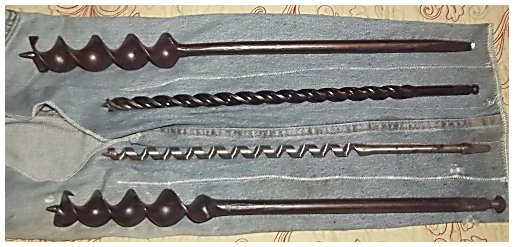

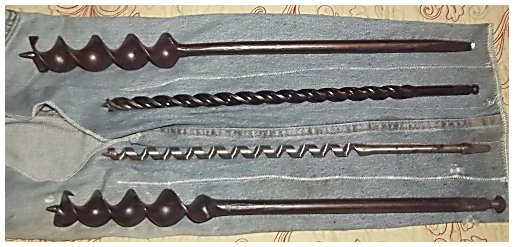

Auger bits,

the two small ones at top for using 1/2" rebar to secure

logs together, the larger two at the bottom are for

wooden dowels. Long dowels can be purchased or

shaped from hardwood using a spokeshave (below). |

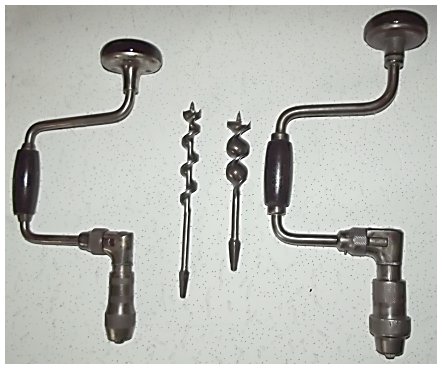

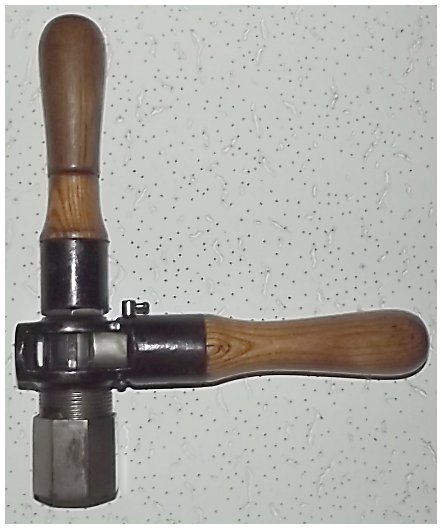

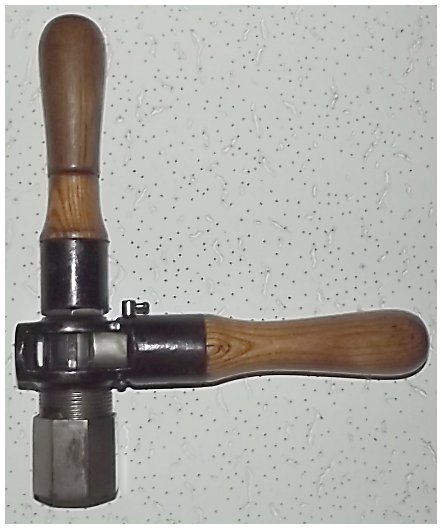

This ratchet

auger handle is for working in tight confines like corners

and window and door frames. The left handle unscrews

and fits on top. The adjustable chuck will hold about any

auger bit. This is a serious auger handle and very heavy. |

`

|

|

|

| Pant legs from

an old pair of Levi's sewn to make a sheath to keep the

auger bits secure in storage. When stored like this

the cutting edges don't get banged around and stay sharp

and clean. |

Part of a leg

from old Levi pants for storing the auger handles so they

are always clean, rust free and ready to use. |

|

|

|

| A brace and

bits are used for shallower holes where required.

The brace is also used with dowel making tools, as shown

below, right. |

The ratchet

auger handle shown above but with the handle fastened to

the top. With this arrangement it is possible to

drill straight holes when working in a corner. The upper

part of the top handle rotates to avoid causing blisters. |

`

|

|

|

| The broadaxe

is used for making flats on logs for foundation

beams and square beams for flooring. This broadaxe

was hand forged over a century ago using high carbon steel

as the cutting edge with softer iron forge-welded to the

top for strength without brittleness. |

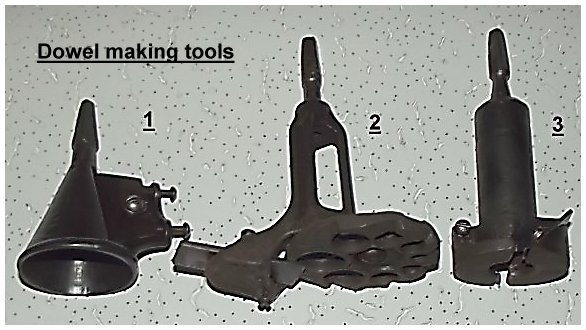

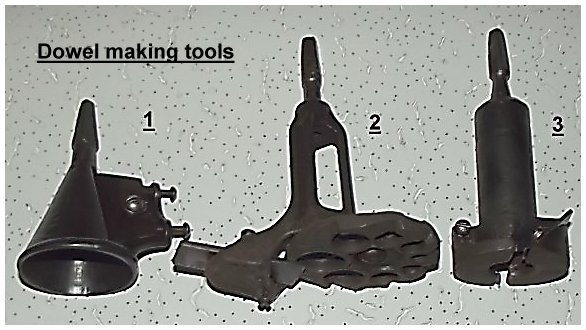

These tools

are used with the brace to make dowels. #1 is the

starter, cutting a tapered cone on a piece of wood.

#2 can make to make a dowel to fit the bit used to make

the hole. #3 is used when a square shoulder is

needed at the end of a dowel, such as when making

primitive furniture. |

|

|

|

| Draw knives

are used to remove bark and to shape logs, make flats on

logs, etc. The 6" draw knife is very handy to carry

and use when needed, but the handles are too close

together for working large logs and thus can cause real

knuckle bruising. There IS a use for large

fixed-handle draw knives, but for little jobs like tool

handles and small logs, these work fine. |

This shows why

I like folding handle draw knives - a sheath can hold one

right on a tool belt. |

Ancient adjustable-handle

draw knife

|

|

|

|

Above is an unusual adjustable-handle draw knife. The

handles don't fold, they rotate to any upward position and

lock in place, and can be removed for compact storage.

This draw knife was made by

Watrous & Co. in Elmira, N.Y.,

based on the

Richard N. Watrous patent of Dec. 15 1857. Watrous

went out of business in 1883 and it is impossible to date

this tool closer than that. And it still works!

|

`

|

|

|

| A froe is used

to cut roofing shingles from a "bolt" of 3 foot long,

knot-free cedar. This particular froe was made in

Langlois, OR in the 1930's from a truck leaf spring

and the handle shaped with a spokeshave. |

A leg vise is

a super-duty vise and clamp used for forging and metal

work, and holding tools for sharpening. At least a

century old, after my refinishing it looks and works like

new. |

`

|

|

|

| Old

spokeshaves, dual blades, one curved, one flat.

These are used for making spokes for wheels, of course,

and also make tool handles. |

A new inside

curve spokeshave, stainless steel, from Lee Valley Tools.

A handle or spoke is tapered flat at one end, round

tapered in the middle, and then curved up to the size

required to fit into a tool head. This was a

Christmas gift to me from a very special friend. |

`

|

|

Spokeshaves are lumpy and have

sharp corners. I make belt sheathes for spokeshaves

using thick canvas with inserts cut from the corners of

gallon milk jugs. The inserts are shown at left,

then covered with another piece of thick canvas and sewn

into the shape required to hold the spoke-shave. One side

has a belt loop sewn on, as shown above. The halves are

then sewn together and Zig-Zag stitched around the edges.

The result is a sturdy belt sheath that conforms to the

odd shape of a spokeshave and the plastic inserts prevent

wearing a hole through the canvas over sharp points and

ridges in the tool. |

|

`

|

|

|

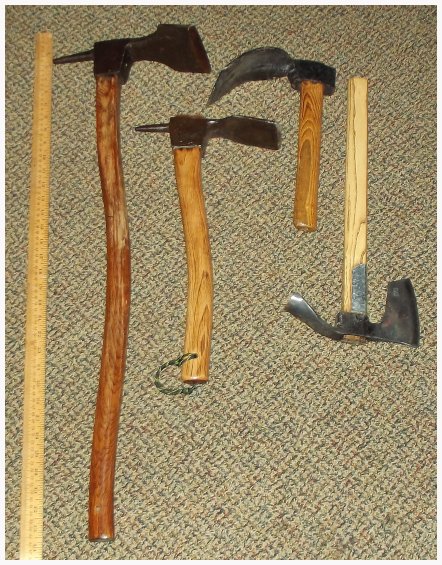

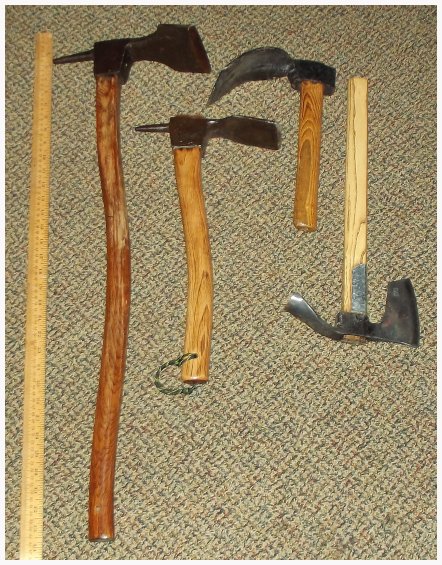

| New hatchet/adze tools made by a fellow in

Bulgaria who sells these and many other hand-forged tool

on eBay (World

Thracian Pickers). His handle on the bottom one, the top one

has a hammer handle I fitted and finished. |

A selection of adze tools. Long

handled at left is at least a century old. The

short-handles curved adze (3rd from left) was Italian

military issue for making log walls in trenches. |

`

|

|

|

| A child's

bench seat made very quickly using a slide off a log.

The bench is drilled for legs. |

The legs are

cut from limbs and a dowel maker on a brace (see above) is

used to make dowels to fit the holes drilled in the seat

at left. |

The Ultimate in Recycled

Tools

|

|

|

| Three knives

hand forged from old files. The handles were made

from dry hardwood found in the forest, shaped and riveted

in place using nails for rivets and copper pennies as

washers. |

The leather

for the sheath was from an old tractor implement power

belt found in an abandoned barn, hand riveted so the

knives all nest as shown above. The cost? Some

nails, rivets, and pennies. |

|

|

|