|

SITE

INDEX

QUICKENING

NEWS

PREPARATIONS

1.

Food

2.

Manna

Meals

3.

Water

4.

Sanitation

5.

Medical,

health

6.

Kerosene heaters and cookers

7.

Lighting

8. Wood

cooking and heating

9. Communi-cations

10. Essential

Tools

11. Home

built items

12.

Electrical; generators

and power

13. War

preparedness

14.

Gardening

SITE

INDEX

Miles Stair's SURVIVAL

SHOP

HOME

RADIATION

INDEX & JET STREAM

PROPHECY

COMMENTARY

BY MILES

BOOKLETS

BY MILES

GUEST

SUBMISSIONS

PHOTO

INDEX

LINKS

SITE

INDEX

Miles Stair's

SURVIVAL

SHOP

|

|

Water Hand Pump

I wanted a hand water

pump just as a backup source for very long term contingency

planning. A standard pitcher pump would not work as they

still require carrying water in buckets. A sealed

pitcher pump was the answer. A sealed pitcher pump

can be connected to household pipes, often by backfeeding

through existing plumbing, so the water can be pumped directly

into a house - sinks fill, toilets flush, etc, and all without

carrying water!

As the pump would not be

used for long periods of time, a PVC pump made more sense than

a traditional cast iron pitcher pump. UV radiation

damage was not a concern because the pump would be located

indoors in an existing well house.

The wells in my area go

down between 90 and 100 feet for water. A standard pitcher

pump is limited to about 20 feet of depth. A pitcher

pump will operate that deep, but only with the pump sitting

directly over the well casing with a long operating rod to

pull a leather washer at the bottom of the well to PUSH water

to the top. Such a water system will indeed work if

there is no alternative for potable water. I did not

want an exposed system like that nor did I want the extra

effort required to pump the water from that depth.

It took quite a bit of

witching with copper rods, but I found a shallow well source

that was very low capacity, low recovery, but certainly good

enough for a hand pump. I hit water at 18 feet, and it

was below the clay layer so it was not surface water, hence

contamination was not an issue. The well hole was dug

with a auger-style post hole digger, adding 4' sections of

3/4" galvanized pipe as needed to dig a hole 20 feet deep. It

was hard work. For a well casing I used thick-walled 3"

PVC pipe. The standing water table inside the casing is

up to 10 feet from the top of the well.

|

|

|

Above, the Oasis Pitcher Pump installed

|

Exit plumbing to base of small pressure tank |

The pump I chose was made

by Oasis. It was advertised as being black and having a

replaceable suction pump, but that was a lie. I was sent

a blue sealed unit that cannot be repaired. It

does work but is not the pump advertised and shown on the web.

|

The installation shown on this page is not finished and ready

for winter. |

The Details

Installing the pump and

getting it working following the factory instructions was

impossible. The instructions call for using a 2"

diameter well pipe and no foot valve. Total insanity.

Deep well hand pumps have a long lift rod to pull a cup that

pushes water to the surface. The wider the cup the more

water that can be pushed upward. A shallow well hand

pump, however, uses suction to bring water to the pump, yet

the instructions still call for a 2" drop-pipe in the well

casing. One foot of water in a 2" pipe is 0.163 gallons.

My 18 foot long drop-pipe would thus have to lift 24.48 pounds

of water - by suction alone! That is not going to

happen. In actual trials the hand pump would not lift an

18 foot long column of water in a one inch pipe - 0.0141

gallons per foot, 18 feet of water weighing 6.12 pounds.

Just as a test I used a 5/8" garden hose with a 3/4" foot

valve as a drop-pipe and the hand pump finally pumped water!!!

The hand pump will suction 3 pounds of water up 18 feet without much effort required

for pumping.

The output for my system

using a 5/8" garden hose drop-pipe averages 3 gallons

per minute of pumping at an easy rate and light effort that

can be sustained for awhile. It takes 1 1/2 gallons of

water per toilet flush, on average, and perhaps 6 gallons of

water to wash dishes or clothes by hand. The hand pump can

provide sufficient water for normal sanitation requirements,

where "normal" would be an absence of electricity and hot

water means heating water in a stock pot on a

kerosene stove and washing

clothes with a scrub board and wringer for line drying.

The factory instructions

say to remove the check valve if using a foot valve at the

bottom of the drop-pipe, or drilling a small hole in the drop

pipe below the front line to relieve pressure. Of course

with the new glued-together pump design it is impossible to

remove the check valve. It does not matter. The

pump will work just fine with the check valve in the pump AND

a foot valve at the bottom of the drop-pipe, and the pump does

not have to be primed before every use.

The supplier also says

the hand pump will build pressure to supply the second-story

of a house with water. I could get to 10 pounds of

pressure, but anything more than that required too much effort

to make it worth while. It would be possible to pump

water to a second floor, but the effort required would be

substantial. For pumping higher than the first floor of

a home a small pressure tank such as the one I installed will

make the work a little easier. The system works better by using

gravity flow, pumping into a container higher than the sinks

in the house, with water flowing via gravity from the

container (or small pressure tank) to the house.

|

|

Left, the well is 20 feet deep, water up to

10 feet from the top.

The white 5/8" hose drops to within 6" of the bottom of the well

and has a 3/4" foot valve. The area around the well

casing is sealed with concrete to keep out surface water.

Right is the modified bucket for

priming the well. The hose from the bucket connects to the

right side of the "Y" at left. |

|

Above left shows the

heavy-wall 3" PVC pipe I used as a well casing. Just above the

surface I placed a 3" x 3" x 1 1/2" "T" fitting, as shown.

A full-flow 3/4" "Y" fitting attaches to the end of the 5/8"

hose used as a drop-pipe. The right side of the "Y"

leads to the hand pump, the left side has a washing machine

hose attached which leads to the blue bucket shown above

right. To prime the drop-pipe the bucket is filled with

water, both valves opened, and water can fill the drop-pipe

via gravity rather quickly because the displaced air can

escape up the hose and through the water in the bucket.

It would seem logical to use a garden hose from another source

of water would lead to faster priming, but that is not true

because there is no way for air to escape from the drop-pipe

and line to the hand pump. A simple bucket connection

not under pressure allows air to bubble up so the drop-pipe is

properly filled ("primed") with water. After

initial priming the bucket and hose can be disconnected and

saved for the next time it is needed.

Those living in areas

where it gets really cold will need a set-up like the priming

bucket shown above. To protect the pump and lines from

freezing, a tiny hole can be drilled below the frost line in

the drop-pipe. That will drain the water down to the

small hole to prevent frost damage to the pump and water

lines, but it will mean that priming is necessary before

the pump is used again. The priming bucket is simply a

very fast, easy means of priming the drop-line and hoses/pipes

leading up to the pump.

It should be noted that

this is a test set-up. Before winter the hoses will be

re-routed and covered to be frost-free...and then not be

visible for photographs.

|

|

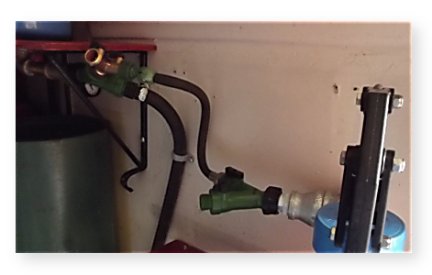

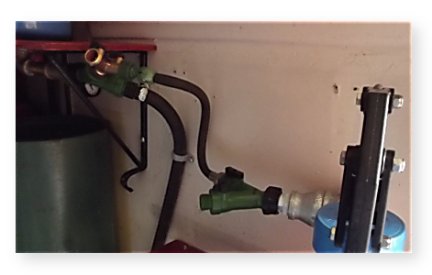

At left, the plumbing under the pitcher pump.

The full-flow "Y" connector on the right side is from the well,

the left side is for priming the pump. See the bottle in

the top left photo that is connected to the hose for priming the

pump - it is visible to the right on the wall behind the hand

pump.

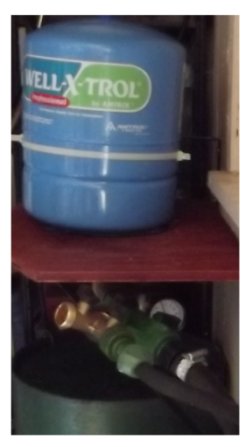

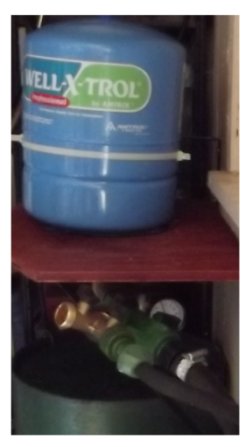

At right, the 2 gallon pressure tank.

The right side hose is from the pitcher pump, the left side is

for draining the tank - bleeding the system. The hand pump

is capable of pumping up to 10 pounds pressure, but it is a lot

of work. In actual use the tank is merely an accumulator

and conduit for water to flow via gravity to the house.

|

|

|

Above left. Connected

to the bottom of the Oasis Pitcher Pump is a 2" x 3 1/2" galvanized

nipple, a 2" to 1 1/4" galvanized reducer, a plastic 1 1/4" to 3/4"

reducer and a 3/4" NPT to 3/4" garden hose adapter. The extra

capacity for water directly under the pump with these adapters

allows for easier filling of the pump chamber. |

Above right.

The pressure tank 3/4" connection is fitted with a 3/4" NPT to 3/4"

garden hose adapter, then a full flow 3/4" "Y" valve with individual

shut-offs. One side of the "Y" is connected to the pump with a

short section of 3/4" garden hose and the other side with a 3/4"

garden hose to a "T" connector to a galvanized pipe leading to the

house water system. |

Water from the small pressure tank

goes through a 3/4" hose to connect with a "T" fitting on an existing

3/4" galvanized pipe from a 93' deep well, the pipe being used to

transport water to the house and gardens for irrigating. The pressure

tank is 3 1/2' above floor level, so water being pumped from the hand

pump will flow into the house and fill toilets, sinks, etc, without the

need for carrying buckets of heavy water back and forth from house to

well. The hand pump with connected full-flow "Y" valves allows the

hand pump to be used to prime the deep well drop-pipe if required,

simply by opening the connecting valves.

The reason I used 3/4" garden

hoses and "Y" connectors is that they permit the entire system to be

easily disconnected for repairing, relocating, etc. To maintain

versatility, on the exit plumbing from the pump I used a 1 1/2", 90

degree PVC angle with 1 1/2" threads on one end and solvent glued the

straight end into the pump. Next came a 1 1/2" to 3/4" galvanized

reducer and a 3/4" NPT to 3/4" garden hose adapter (see photo at

top right). The outlet size of the pump itself was therefore left

at full diameter of 1 1/2" if that size was ever needed in a different

application, and the 3/4" hose from the outlet to the pressure tank will

flex under pressure and not develop a leak as can easily happen with

rigid plumbing.

Every hand pump installation is

different. There is no "one way" that is "correct" for every

possible contingency and requirements. I was lucky and found an

underground water source close to where I could easily plumb the system

into an existing well house. A good friend of mine found a shallow

depth water source on his property about 75 feet from his house.

He already had a pressure tank in a basement and lives where it is

colder, so plumbing from the well to the house is buried beneath the

frost line. He can pump indoors into his existing house plumbing

without going outdoors in stormy weather or snow.

The hand pump in my installation

is mounted to a sturdy 3/4" plywood table attached to a wall with strong

shelf brackets. The table height is very important and is one of

the reasons you should do as much of the installation yourself as you

possibly can. The operating handle on the hand pump is

pushed down to pump water, with most of the pressure (and therefore

effort) being at the end of the stroke, just before the handle is

vertical and beside the body of the pump. You should not have to

lean down or raise your arm too much when pumping - the ideal pump

stroke ending in a natural movement that is comfortable. It can

take several different trials of various heights for the table before a

good height is attained - I moved my table three times to get the right

height. If a plumber installs the entire system it likely will be

sized to fit the plumber, not you.

Extra fittings, either "Y"

adapters or "T" connectors, should be installed very close to the

well-head and just under the pump. Not only will those fitting

permit easy priming of the pipes and hoses, they will permit the entire

plumbing system to be cleaned and sanitized when desired. Let us

assume the well is located some distance from the hand pump. The

priming bucket system I show above can be connected to a "Y" or

"T" fitting at the well. The fitting under the pump can have a

short length of hose attached that drops into an empty 5 gallon pail.

The priming bucket is filled with a 25% bleach solution, set on a

sawhorse or other bench higher than the outlet, and the valves opened.

The bleach solution will then flow via gravity the entire length of the

pipe and cleanse it thoroughly. Without those fittings the well

itself would need to have much more bleach poured directly into the

well, then the hand pump operated for a long time to move all the bleach

water through the plumbing. A plumber is not likely to even think

of installing the extra "Y" or "T" connectors to enable easy flushing

and cleaning of the plumbing, another reason for doing the work yourself

and getting it right the first time.

THE END RESULT

With my hand pump set-up I can

quietly pump potable water in the absence of electric utility company

electricity for normal pumps or a noisy generator to power an electric

pump. Should an EMP pulse disrupt the power supply or other nasty

events happen which required discreet, non-attention getting methods of

getting water, this hand pump system will provide enough water to keep

body and soul together for relatively normal living and cleanliness.

Note: Some people prefer to

have a well bucket system ready to use if the power goes out for an

extended period of time. The advantage is that a well-bucket is

portable: if you move, you can take the well bucket with you

easier than pulling pipes out of a well as with a hand pump as

illustrated above. Of course the well bucket system could not be

effectively used again unless one know the depth of the well at a new

location and had sufficient cable to reach to that depth, but that is a

minor problem compared with having a well-bucket and pulley system in

hand for emergency use. One such well bucket system is produced by

Well WaterBoy Products.

http://waterbuckpump.com

|

|

|