his is to be a brief

introduction to blacksmithing, an art and a science that is so

old as to be almost beyond reckoning. I cannot possibly attempt

to make a Master Smith out of everyone who reads this article.

There are many books written on the subject, and the authors,

those learned scholars who wield the hammer beside forge and

anvil would be most upset if they found out that I could teach

the subject in one article, especially considering that I am only

a "shade tree" smith myself.

his is to be a brief

introduction to blacksmithing, an art and a science that is so

old as to be almost beyond reckoning. I cannot possibly attempt

to make a Master Smith out of everyone who reads this article.

There are many books written on the subject, and the authors,

those learned scholars who wield the hammer beside forge and

anvil would be most upset if they found out that I could teach

the subject in one article, especially considering that I am only

a "shade tree" smith myself.

I am not prepared to say which comes first; the Mark of the

Beast, the Rapture, or Tribulations. Either of the former events

will be immediately obvious. Proceed accordingly, depending upon

how the events unfold. Tribulation is a relative term. Suffice it

to say, however, that the Biblical version of Tribulation is not

something on the order of having Windows crash on you.

I am not prepared to say which comes first; the Mark of the

Beast, the Rapture, or Tribulations. Either of the former events

will be immediately obvious. Proceed accordingly, depending upon

how the events unfold. Tribulation is a relative term. Suffice it

to say, however, that the Biblical version of Tribulation is not

something on the order of having Windows crash on you. For the purpose of these pages of text, I will define the

post-Apocalyptic world as one in which a major cataclysmic event

of some kind has occurred, or is about to occur that will

severely disrupt society. Our distribution network will have

broken down, and widespread law and order will become a thing of

the past. Only little pockets of order will exist in a sea of

chaos.

For the purpose of these pages of text, I will define the

post-Apocalyptic world as one in which a major cataclysmic event

of some kind has occurred, or is about to occur that will

severely disrupt society. Our distribution network will have

broken down, and widespread law and order will become a thing of

the past. Only little pockets of order will exist in a sea of

chaos.

A post-apocalyptic smith will not necessarily be a replica of the

Master Smith of 1776. There will be gaps in his knowledge that

only experience not presently available can fill. Many modern

smiths do not, for example, know how to make files or shoe

horses. They will, however, have a wealth of knowledge and

materials that would amaze our 18th century Master Smith. They

may have Templesticks, a power hammer, modern steels that are

air-hardened. They'll understand some science and engineering

that their forebears never heard of. They will find,

unfortunately in many cases, that they'll have to go back to hand

tools rather than electrically powered machines. They will find

that they cannot order propane, coal, steel, acetylene, oxygen,

or other items now commonly ordered by phone or on line. They'll

have to make do... something most smiths have had to learn even

in these times.

The blacksmith of old was the original Angus MacGyver, and

had to be at least as inventive as that television character. Who

do you think made the first Swiss Army Knife anyway? The

post-apocalyptic smith will have to be even more inventive than

his forefathers.

The blacksmith of old was the original Angus MacGyver, and

had to be at least as inventive as that television character. Who

do you think made the first Swiss Army Knife anyway? The

post-apocalyptic smith will have to be even more inventive than

his forefathers.

The answer to the basic question (why to learn smithing in the

first place) is fairly self-evident to a "born" smith, someone

who wants to learn it just for the sake of learning it; he does

it because he can and he needs no further justification for it.

Anyone else, particularly those reading these words on Miles'

site, might need some additional motivation. He might ask, "How

will learning to do blacksmithing help me survive the end times,

or any other disaster?"

Well, life in a post-Apocalyptic world will not be easy. The

things we have all become accustomed to, like toilet paper,

feminine hygiene products, dry-cell batteries,

state-of-the-automotive-art Maybach automobiles (if one is

extremely weathy!), and telecommunications will all either be

gone completely or sharply reduced in availability. We will have

to find substitutes or trade for what we want.

I like honey, for example, but I absolutely HATE bees (You

wondered why I didn't buy the bee book, Miles?). After a nuclear

war or some natural or supernatural disaster, I won't be able to

go to Aldi's or Sam's to buy honey. I'll have to raise the bees

myself, trade other goods and services, rob a beekeeper, or do

without honey. If I thought that I could control my nerves well

enough to actually open an active hive and rob the bees of their

labor, I might consider learning how to raise the little venomous

flying thorns myself, but I don't think I could do that... hey,

even Superman has a weakness! This leaves brigandage and trade.

One is costly, one is risky and immoral. I would choose to

trade.

Trade what? Well, the beekeeper probably isn't a blacksmith, and

like me, he can't go to Fleet Farm to buy tools that he needs to

ply his trade. He, like everyone else will need to find other

sources for axes, shovels, hoes, picks, wedges, hooks, and a

thousand other tools. I need a quart of honey, he needs... say, a

boot scraper for outside his front door to keep the mud out of

the house (no electricity for the vacuum cleaner and he probably

has other things for his wife to do than wear herself out

sweeping up dried mud). Or maybe he needs a hook to hang his

lantern on when the sun goes down. Possibly he might need a

spring for his shotgun to keep the bears out of his hives.

He might want something nobody ever heard of, like, for instance

a 'skeeter chaser (pictured at left). Mosquitoes and other

insect vectors spread more disease than all the sneezes in the

world.

Virtually any essential tool can be made by a skilled blacksmith

using only the basic tools of hammer, forge, and anvil. You need

a fish-hook? Can do! How 'bout a horse shoe? No problem at all!

It might pay to remember that gasoline not being available will

make horses extremely popular all of a sudden... which will make

farriers quite sought after.

A word about farriers... a good farrier, which is a blacksmith

who specializes in horse shoeing and related enterprises is worth

at least his weight in gold. He must be part blacksmith, part

veterinarian, and it doesn't hurt to know something about

wainwrightry and harness mending. A farrier can do most simple

blacksmithing tasks, though he may not be up to things like

hardening and tempering knife blades or making a file from

scratch. A blacksmith who is not trained in working with horses

should not attempt to shoe a horse. He could end up crippling a

valuable animal... and the owner might then become upset enough

to find a new place to shove the smith's hammer... after first

heating the head to red heat in the forge!

Any steel tool can be repaired and/or refurbished by a competent

blacksmith. Many a modern smith makes a fair amount of his living

from refurbishing plow points, or at least he did ten or fifteen

years ago. Picks, axes, shovels, mattocks, broadaxes, froes,

adzes, hoes, and other hand tools do break and wear out. They'll

be needed, quite probably, within the time span addressed by

other areas of Miles' site. Many essential tools will be broken

and need repair... probably more repairs will be needed than new

tools, though this will depend upon many issues as yet

unknown.

This is not to say that trade is the only reason to get into this

kind of work. Indeed, most farmers would still find basic

smithing skills useful, even in the age of electric arc welders.

I was able to persuade a modern dairy farmer to part with his

grandfather's forge only with great persistence and the promise

that I would see to any future blacksmithing needs he might have.

I've since straightened a wagon tongue and a steel lever, and

repaired "obsolete" farm machinery, among other things.

The three basic tools of the smith (hammer, forge and anvil) can

and must be supplemented by a whole bunch of other tools, but

every one of those tools from a drill bit to a rotary forge

blower can be made with the three basic ones. The most commonly

used hand tool in my shop is a two pound cross-peen hammer.

The two on the bottom in the illustration at left are

cross-peen hammers. The astute observer will note that one has a

longer handle on it. Both weigh the same, but the longer handle

gives the smith more leverage and allows for a more forceful hit.

I use this one for rough work like squaring round stock. The

shorter handled hammer is used for finishing points, bending, and

welding of light stock.

Most smiths use a heavier hammer than two pounds, but they are

usually in better shape than I, work with heavier iron, and have

a much larger anvil than I do. I sometimes use the 4 pounder for

heavier stock, but not often. I don’t think I would crack my

anvil face, but I don’t especially want to find out.

Almost any hammer will work for smithing... even that little 10

oz hammer your wife uses to hang pictures in the living room,

though to do any significant amount of work, you'd have to do

quite a bit of hammering with something that light. It is best to

get a hammer in the two to five pound range at a minimum for

general blacksmithing, but even better to have an assortment of

hammers in different weights and configurations. Brass, and lead

hammers do have their uses in blacksmithing, as do wooden

mallets, but in a pinch they can be done without. I find them

useful for adjusting work clamped to a drill press table and

straightening out bends that find their way into longitudinal

twists.

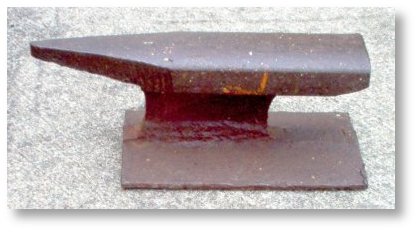

An anvil, at least a quality anvil, is one of the more

difficult items to find these days. My own anvil, pictured at

left, is a relatively small and light model made in China and

sold at Fleet Farm (on clearance) more than twenty years ago. It

is a traditional one in that the body of the anvil is made of

wrought iron and the face of tool steel welded onto the body. It

has served me well for some twenty odd years and will likely last

another twenty. Unlike most modern anvils, my anvil rings just

like the old ones did. Modern anvils are almost all made of cast

steel, thus they do not ring. This is not as bad as some smiths

will tell you.

The old London pattern anvil or slight variations thereof, is the

most common anvil in public perception. This is the anvil that

commonly gets dropped on the heads of cartoon characters from

great heights. It has a horn, a face, a pritchel hole, and a

hardy hole near the heal of the anvil.

A common variant is the farrier's anvil, which is generally

lighter in weight, and has a longer and more tapered horn. Other

designs may have two horns or other design variations. They can

weigh anywhere from a thousand pounds or more in the case of a

shop that does steam locomotive repair or traditional anchor

making, to a few ounces for a jeweler's anvil. If you can afford

to buy an anvil, get one that weighs at least 150 pounds or so...

heavier is better, but if you are trying to bug out of town with

your family in a '91 Ford Escort, a 500 pound anvil in the back

will almost certainly overload the suspension, not to mention the

back of the smith who has to lift it.

I have found that my 50 pounder is heavy enough for most small

household hardware like hooks, trivets, fireplace tools, etc. It

is also easy to move around my garage. Would I trade it for 150

pounder, though? Absolutely!

If you have to improvise an anvil, a section of railroad track

will work, as will a section of steel I-beam. Almost any kind of

heavy steel will work. Cast iron, like an engine block does not

make a very good anvil. Cast iron is brittle and will shatter

upon impact with a hammer. Probably the first anvil was simply a

large rock, and while a piece of granite is not my favorite

anvil, I have been able to use it for some purposes.

The anvil at right is made from a section of railroad track and

has served Miles for quite some time. An anvil like

this one does have limitations, especially when working with

very heavy stock, but you can use it for a surprising number of

things. Most common tool repairs can easily be handled with

this anvil.

one does have limitations, especially when working with

very heavy stock, but you can use it for a surprising number of

things. Most common tool repairs can easily be handled with

this anvil.

An important consideration with this type of anvil, or any light

weight anvil is the fact that it will soak up heat from the hot

iron being worked on its surface. When I am working with

any stock larger than half an inch in diameter, I generally put

my anvil in the slack tub for a few minutes after every two hours

or so. As a rule of thumb, if it becomes too hot to touch,

it is too hot!

The anvil is mounted traditionally by spiking it to a heavy

wooden post sunk into the floor a fair distance with the face of

the anvil about knuckle-height to the smith. If you want it

lower, be my guest, I suspect that chiropractors will still be

plying their trade in the foreseeable future. I mount mine on a

box made of 2x12 stock held together with long carriage bolts and

filled with concrete capped by another piece of wood. This is a

fairly stable support and can be moved... with difficulty, as it

weighs more than the anvil.

Instead of being spiked, my anvil simply rests in a rectangular

recess sized to fit its base. This allows me to remove the anvil

and move it separate from the base. Other smiths use a steel

frame support and some chain the anvil down. This, they tell me,

keeps the anvil from ringing as loudly. To each their own.

You also need a forge.

The forge can be as simple as a fire built on the ground with a

"trench tuyer" and three "slaves" using their lungs and a long

tube each one in sequence to provide a forced draft as it was

done in times past. Now, slaves, by nature are not very good

workers, being unwilling ones... not that I blame them.

Volunteers fail as well, as they require food, shelter, and other

human needs just like the slaves do... but in a pinch, a group of

men with a good sense of rhythm can serve in this fashion for a

time. There are better ways, however.

The forced draft is essential. Naturally aspirated fires simply

do not provide enough heat to work iron and steel unless they are

quite large. This can be done, as, I have been told, the

traditional Japanese swordsmiths do, but a large fire consumes

proportionately large amounts of fuel and the immense heat from

such a fire makes it difficult to approach the iron being

worked.

Almost everyone even in these modern times is familiar with the

common fireplace bellows. This small bellows is called a

"single-acting" bellows, because it can only provide a forced

draft when being pumped in one direction.

The double-chambered or great bellows is similar in operation,

but it has two chambers and can provide a steady draft by virtue

of the design allowing for draft production while being pumped in

either direction. While a pair of single-acting bellows can be

used in tandem, a double-chambered bellows is preferred. The size

of the bellows depends upon the size of the forge, which in turn

is dependent upon the size of the metal to be worked.

Probably the best compromise package is either a modern or an

antique forge with a hand-cranked rotary “squirrel-cage” blower

to provide draft. The rotary blower was invented around 1850 and

has pretty much supplanted the bellows due in part to its compact

size relative to the bellows it replaced.

My own forge is one of these. It was built by the Buffalo

Forge Company of Buffalo, NY, probably in the early 1900's. It is

made of heavy cast-iron and provides useful heat for most things

I need it for. I obtained it from a friend and when I picked it

up, the blower was froze up from rust and lack of use. Some of

the parts were bent from where it had been crushed against the

back wall of a shed by a trailer carelessly backed into it. I've

since restored it to working condition with minimal expense.

This is what you want, if you can possibly find one. The modern

ones are available from several sources, and the old ones can

sometimes be found at farm auctions.

If you cannot locate or cannot afford a forge... all is not lost.

The first forges were made from scratch. Forges can be made from

masonry, or iron and steel. I've made forges constructed out of

brick held in a wooden box with a piece of black iron pipe as a

tuyer... the tube providing the draft to the fire. Never use

galvanized pipe for any forge part that will get hot... unless

you would like to experience lead poisoning first-hand. I've also

used brake drums for the "duck's nest". Brake drums work fairly

well, being made of cast iron. Anyone capable of performing basic

smithing operations should be well-able to engineer his own

forge... and there are numerous sources available for those not

able to design their own.

It is often helpful to have a "blacksmith's helper"... a support

that is the same height as the edge of the forge. It is

useful to have such a device adjustable to account for

variations in the level of the floor as well as the angle one

wishes the work to be held in the fire. At right can be

seen an improvised helper, a saw-horse. There are iron

helpers, but for light work, a wooden support is more than

sufficient.

to have such a device adjustable to account for

variations in the level of the floor as well as the angle one

wishes the work to be held in the fire. At right can be

seen an improvised helper, a saw-horse. There are iron

helpers, but for light work, a wooden support is more than

sufficient.

Another item that is needed is some kind of container for

quenching steel and supplying water for cokification of the coal,

or containing the fire in the case of a charcoal forge. This is

called the slack tub, and is essential. I use an old

whiskey barrel sawed in half, as can be seen in the photograph,

but any kind of bucket or tub will work so long as it is

water-tight and relatively heat resistant.

In addition to the slack tub, you also might want a container of

oil and/or brine. Not all steels can be effectively hardened in a

simple water bath. There are, for example, oil-hardening

steels. Caution: plastic buckets and the like do not

make good slack tubs, especially when containing oil. They

will melt and possibly cause a large oil spill in your

driveway.

A forge traditionally burns coal or charcoal, though they can be

designed to burn various petroleum products, alcohol, wood, coke,

natural gas, wood gas, and propane. If it will burn, you can

probably design a forge to burn it... though some fuels are more

preferred than others. Probably the most useful fuels for a

post-apocalyptic smith are the traditional ones; coal and

charcoal. Most of the others, natural gas, propane, etc. will not

be available in any reliable quantity.

Coal suitable for smithing is not at all easy to come by

commercially any longer. I used to buy it from a local coal

supplier, but now they only supply stoker coal, which is a

high-sulfur product in very large granulation. It can be used,

but it doesn't work well at all. Smithing coal can be ordered in

fifty pound bags, but be prepared to pay for shipping... coal is

heavy. Coke, which is what you convert the coal into when you

burn it in a forge, can be burned as well... if you can find it.

The best coal (or coke) for smithing has a very high percentage

of carbon, and a low percentage of sulfur and other

impurities.

The "shelf life" of coal, coke or charcoal is in the millions of

years... much longer than you need to store it, and it can be

stored out in the weather with no problems. Unless you live in an

area where you can "strip mine" it on your own land however, you

can't make it yourself, so get a few hundred pounds in storage

against the time when you can't order it any longer... more if

you plan to "hire out" your services to the neighbors.

"Shot coke" is a petroleum product, and does not work well for

smithing due to an extremely high sulfur content... take in a

lung full of the fumes from that stuff some day. After you have

finished your coughing spell, you'll understand with a great

wealth of detail why you don't want to use it if you can possibly

avoid it.

Charcoal is pretty much the antithesis of coal in many ways. It

is almost pure carbon, with no sulfur or anything else to make

the thick black smoke that characterizes a coal fire. It is

readily available at many distribution points. It can even be

made on-site if one has a ready supply of wood. It is relatively

light in weight. It is not without problems, however.

First, the forge must be designed with a much deeper bowl than a

coal forge in order to produce useful heat. A coal forge can burn

charcoal, but it must be modified a bit. When I burn charcoal in

my own forge, I generally stack a few rows of bricks around the

periphery to improvise a deeper bowl. Alternatively,

one can simply mound it up over the top of the fire.

The best charcoal is "natural lump" charcoal, which looks like

blackened tree branches, or in one case I saw, blackened hardwood

flooring scraps. Conventional charcoal briquettes intended for

outdoor cooking have some problems... the binder in this product

will break down if exposed to excessive moisture, and I have

heard that it will produce toxic fumes under a draft. I question

this claim, but I cannot refute it, so use charcoal briquettes

for smithing at your own risk.

Probably the biggest drawback for charcoal is that it burns up

much faster than coal does. A hundred pounds of coal will be

enough to supply my own forge for the entire Summer, a hundred

pounds of charcoal will be gone in a month or two.

Should you wish, you can make your own charcoal. Alex Bealer's

book contains some references to the subject as it was done

historically, and is done today. Not all that much has changed in

the basic process. Charcoalers build fires in piles of wood that

are partially buried in the earth. They open drafts up to let

varying amounts of air in to the fire from time to time until the

charcoal is done, and then they smother the fire. This is a very

simplistic version of what they actually do, however. Most of us

would not have need for such large amounts of charcoal as is

commonly made this way, however. Charcoal making is as much art

as science... kinda like blacksmithing... and those who make it

develop an expertise that is difficult to impart to others who

have not spent time in the woods sleeping under a tarp and

tending fires.

My neighbor Seffe tells me of long hard hours spent in making

charcoal under his father’s tutelage as a boy growing up in

Mexico. He also tells me that the pay for the finished product

was minimal at best. This is, unfortunately (or fortunately, if

one is buying rather than selling) common in the history of

charcoal making.

The basic process is simple; one burns wood under carefully

controlled conditions to burn off the wood gas and moisture among

other things, and leave behind the almost pure carbon that is

charcoal. Hardwood makes the best charcoal, but any wood can be

used.

Making small batches is labor-intensive, but not impossible to

accomplish. One way is to simply build a fire on the ground, wait

for the flames to die down, (an indication that most of the wood

gas has been burned off), and douse it with water. This will

leave charcoal in the ashes that can be gathered up and put to

use in a forge.

Another way that I have found effective is to build a fire in a

commonly available Weber charcoal grill with hardwood. Let the

fire get going pretty well and then put the lid on the grill and

close up the vents. The Weber design is almost perfect for small

scale charcoal production. It pretty much duplicates with modern

air vents and steel, what the traditional charcoal makers do with

dirt. Your first batch of charcoal will probably have quite a bit

of wood left in it. No problem, leave the wood for the next

batch... or simply use it as it is in the forge. You can convert

it to charcoal much as coal is coked in the forge, though you

probably do not want excessive amounts of wood in your forge. It

produces tars, creosote, smoke, etc. that are tough on the

smith's eyes, not to mention his lungs.

The first tool that a smith needs to construct, assuming he has a

hammer, working forge, and an anvil, is a pair of tongs. Tongs

are a tool used to handle small pieces of iron in the forge. In a

pinch, a pair of ViseGrips will work, though the short handles on

them limit their utility somewhat. A piece of iron can be worked

without tongs, provided it is long enough that the smith can hold

onto one end of it without burning himself when the other end is

at red heat. Eighteen to twenty-four inches or more is about

right. This should give you some idea of how long to make the

tongs.

My first and second sets of tongs are not pretty. They are crude

and ugly. I made them myself, though, and I still use them from

time to time. These days, though, I seldom admit to having made

something that ugly!

If you wish, you can order tongs already made. This is

perhaps not a bad idea for the neophyte who is short of time...

which we all may be. However, making a pair of tongs is a good

exercise and by the time the apprentice has finished a pair of

tongs, he will have learned a good deal and will... perhaps... be

ready to tackle the project he made the tongs for in the first

place.

The tongs at left are horse shoe tongs... or that is my

belief. With so many tools, it is not at all uncommon to

find one in a shop that you never saw before. Most often

the smith who used the tool in question is long dead, so you

cannot ask him outside of consulting a medium... something I

definitely DO NOT recommend. These are used, as near as I

can tell, to handle horse shoes in a forge. The cupped jaws

allow for the cleats to be held firmly.

There are a plethora of other tools that can be either made or

ordered. None of them are essential, but all of them are useful.

They include hardies, specialized hammers, clamps, nail-headers,

vises, drills, punches, and so many others that I could not

possibly list them all here.

About vises.... a five dollar vise with a clamp to attaching it

to a work bench is unsuitable for blacksmithing. Your vise needs

to be large, heavy, and firmly fastened to a work bench. It it

can be swiveled in several dimensions, so much the better, but it

must be sturdy and able to take pounding as you may be using it

quite heavily.

Should you be so very fortunate as to find a leg vise... get down

on your knees and thank God profusely. I only recently acquired

one myself, and this after actively searching for twenty years.

Even if you find a damaged one that can be repaired... you have a

prize beyond price.

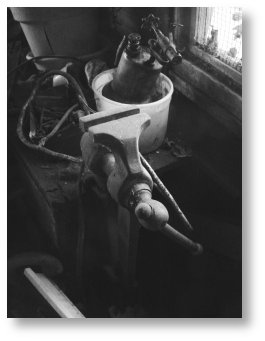

A leg vise has an extension on the stationary jaw

that goes to the floor, thus it is supported right from the floor

and is much sturdier than any bench mounted vise. When something

is clamped in this vise and is hammered on, the force of the

blows is not wasted on the flexing of the bench, it is rather,

applied to the work being hammered.

Traditionally, a leg vise's leg is set upon something like a

white oak post buried a fair distance into the ground, though

this is not my favorite. My own smithy needs to be portable, so I

prefer something on the order of a wedge plate or other support

base that can be picked up and moved along with the rest of the

shop. A plumbing flange and nipple of the appropriate size

makes a tolerable adjustable "foot" for the leg. A concrete

floor with a steel plate supporting the vise leg is pretty hard

to beat, but if you don't have concrete, improvise something

else... a large rock, a post, a steel plate, etc.

I got this vise (shown "as found" in the photo at right) from a

farmer's work bench in Abrams, WI. The present owner of

thefarm had little use for it after his father's death, so it

stood idle. When I came to remove the vise, it hadn't been

used in some twenty to thirty years, and neither had the

blowtorch in the ice cream bucket on the bench. The leg was

buried in the dirt floor with the rotted remains of a wooden post

under it.

work bench in Abrams, WI. The present owner of

thefarm had little use for it after his father's death, so it

stood idle. When I came to remove the vise, it hadn't been

used in some twenty to thirty years, and neither had the

blowtorch in the ice cream bucket on the bench. The leg was

buried in the dirt floor with the rotted remains of a wooden post

under it.

Most smiths buy some of their tools and make others. Necessity

being the mother of invention, smiths often make tools that they

will only use one time for some specific purpose. They do this

primarily because they can.

The one "tool" that a neophyte smith simply cannot do without is

a good set of books detailing smithing operations, properties of

metals, and any other subjects that might be thought useful.

Wainwrightry, harness making, and automobile mechanics come to

mind. Yes, smiths can repair automobiles... who do you think made

and repaired the first ones?

Two books I have found to be extremely informative are

The Complete Modern Blacksmith, by Alexander G. Weygers, and

The Art of Blacksmithing by Alex W. Bealer. Both have a

wealth of information in the form of prose as well as diagrams.

Remember, even if I manage to expand this article such that it

becomes more of an e-book than a web article, it won't be

available when the Internet is gone... unless somebody saves the

entire document and puts it out on a packet radio server.

Another tool that can be useful is either a gasoline

or kerosene blow torch. It used to be a commonly available tool,

but today is found more often in antique shops, having been

replaced in the working world by propane torch. Both

the old and the new torches are shown at left. Please

excuse the workbench clutter.

You might not be able to use it once the gasoline is gone, but

until that time, it will be quite useful for tempering steel

tools, soldering (you'll need an old-fashioned soldering iron

that has to be heated up by the torch), etc.. Be careful with

this tool... and make very certain it is in workable condition

before you do something as foolish as actually igniting it. NEVER

attempt to add pressure to a burning blow-torch. If the check

valve fails and sprays gasoline out through the pump stem... it

will ignite with no way to shut off the fuel supply. It is

difficult to get one to actually explode, but if it does, you

don't want to be near it. A good rule of thumb is to always have

a full bucket of water around to pour on the torch if

something... unexpected... should happen. I cannot stress enough

that these torches, while quite useful, are dangerous in the

extreme and as they are all fifty year old antiques now, may not

be in the safest condition.

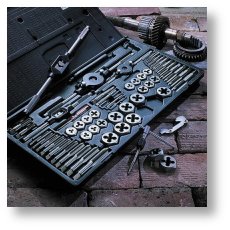

Get a good tap and die

set. The one shown at left is a high-end set by Sears

in their Craftsman line. They make several different sets

in different price ranges. This one contains a set of Easy

Outs. I have personally found Easy Outs to often be

ineffective in removing broken bolts, but the alternatives are

definitely to be avoided. Photo courtesy of Sears.

Get a good tap and die

set. The one shown at left is a high-end set by Sears

in their Craftsman line. They make several different sets

in different price ranges. This one contains a set of Easy

Outs. I have personally found Easy Outs to often be

ineffective in removing broken bolts, but the alternatives are

definitely to be avoided. Photo courtesy of Sears.

There will come a time when you will need to either tap a hole in

something or thread a rod for some reason. Trust me, you do not

want to attempt to cut threads by hand with a file. It can be

done, but is extremely time intensive and has a large scrap

ratio. Cutting internal threads by hand involves first making a

tap, which is done by first cutting threads on a rod of

annealed/normalized tool steel, then tapering the threads at the

end and cutting flutes into it. If this sounds impossible to you

it probably is, though it has been done. Making taps and dies is

not nearly so difficult if one has a properly equipped metal

lathe. More on this topic later.

By now you may have come up with another question; if I can't buy

a shovel at Fleet Farm, where can I order a half-ton of half-inch

square mild steel? The answer is, unfortunately, that a

post-apocalyptic smith may not be able to order anything.

Where, then, can he get metal to ply his trade with? Good

question! Probably the first thing any competent post-apocalyptic

smith would do is to secure a good supply of raw material, mostly

mild steel, but various types of tool steels might also be put

into "stock", as well as a few other metals, i.e.: brass for

brazing, lead and tin for soldering, maybe some copper tubing and

other materials. He might also procure for himself some old

recycled wrought iron or Swedish iron. Preferably, he'd do this

ahead of time, before the waste products hit the fan.

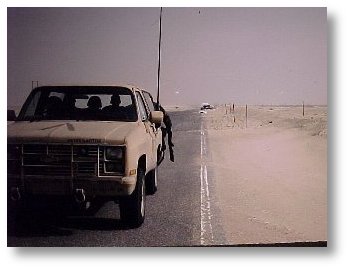

He'd load his stock, tools, forge, anvil, weapons, reloading

equipment, ammunition, food, water, other assorted supplies and

his family, carefully into an old school bus he bought and bug

out to parts unknown. (An old school bus makes a very good

bug-out vehicle because of its large cargo capacity, high

road-clearance, and the nearly bullet-proof sides). But suppose

he did not plan well enough and was caught unawares. (Remember,

not even Jesus knows the hour!) Photo courtesy of www.usedschoolbusses.com.

He'd load his stock, tools, forge, anvil, weapons, reloading

equipment, ammunition, food, water, other assorted supplies and

his family, carefully into an old school bus he bought and bug

out to parts unknown. (An old school bus makes a very good

bug-out vehicle because of its large cargo capacity, high

road-clearance, and the nearly bullet-proof sides). But suppose

he did not plan well enough and was caught unawares. (Remember,

not even Jesus knows the hour!) Photo courtesy of www.usedschoolbusses.com.

Well, look around you. There are all kinds of things in the

average garage or machine shed that won't have much use in a

post-apocalyptic world. A gas or electric lawn mower, for

example. The blade is high-carbon steel, suitable for making

knives, machetes, cleavers, hoes, mattocks, splitting froes, etc.

How 'bout that old side rake? Well, you might be able to use it

as is, but the rake tines are also high carbon steel that can be

used for many things.

The most useful source of base material however, may be that very

school bus that got you out to Gramma's farm in the first place.

(Trust me; at four to ten miles per gallon, you won't be driving

it around all that much after the original trip!) You can jack

the body up and remove the drive train, wheels and suspension.

Leave the body intact as it makes a very good instant shelter and

eventually a good place to store things that need to be out of

the weather. After you finish dismantling the drive train and

suspension, you will have hundreds of pounds of springs,

shafting, and nuts & bolts. Much of this will be good quality

high-carbon steel.

In a post-apocalyptic world, a common ordinary junk-yard is

considerably more valuable than a gold mine. You have at your

fingertips, an almost inexhaustible supply of various grades of

iron and steel bar stock. You have tons of sheet steel, which, as

any smith who has attempted to draw a bar down to a thin sheet

will tell you, is unbelievably precious. You have wire, and

generators, hundreds of radios that probably still work, gears

and transmissions, air-conditioning compressors, batteries...

that can be used as is or broken up for scrap lead which has a

whole 'nother application... as projectiles.

If you are a competent smith and wish to ply that trade in the

post-apocalyptic world, try to locate yourself near a country

junk yard. You will enrich yourself immeasurably not only for

your own projects, but if you can lay claim to that junk yard

somehow, you can supply other smiths with base materials as

well... in exchange for other goods and services, of course.

It is possible for a knowledgeable smith to make his own iron and

steel. This is not to be undertaken lightly, however. Alex Bealer

address this topic in the second chapter of his book. Depending

upon what exactly is wanted, different methods were and are

used.

One method of making wrought iron involves distributing small

pieces of cast iron in a furnace filled with charcoal. The

charcoal is then ignited and the fire fanned to a very high heat.

This will burn the extra carbon out of the cast iron and leave

pure iron and slag behind. This material will collect in the form

of a "bloom" in the bottom of the furnace, where it can be

dragged out and worked with hammers to form various sized rods of

wrought iron stock.

This will not be an easy task to accomplish, and anyone

attempting it should first consult a doctor to make certain of

his own sanity before proceeding. The final product of this

venture however may be well worth the effort.

Actual wrought iron is virtually unavailable today. It hasn't

been made in any form for quite some time, and after about 1900,

wrought iron bar stock was pretty much replaced by mild steel.

Most smiths hated the stuff, but short of making their own

wrought iron, a daunting task, they had to use mild steel where

they had used wrought iron. The advantages of wrought iron may

almost be worth the effort, however. It is far easier to weld

than any steel, one cannot burn it at any temperature... it will

melt first. It is much more resistant to rust than mild steel.

This is the stuff from which you want to make hooks that will be

used outdoors.

There are still a few sources for wrought iron. It is expensive,

but it might be worth stocking a few hundred pounds for certain

purposes... if one has the money. Swedish iron is very much like

wrought iron, but has less slag content and is more expensive.

It, too, is available in limited quantities.

Stainless steel is interesting material to work with. It cannot

be welded in a forge. It retains heat well and it can be used to

forge implements that are virtually indestructible as far as rust

is concerned. If you really try hard, you can get it to rust, but

it won't be an easy task. There are different grades of stainless

steel. The most rust resistant is not magnetic and is generally

softer. Surgical steels, some cookware, and other food grade

machinery is made of this stuff.

Other tools might be desirable. In the way of power tools, a

trip-hammer or power hammer will save many hours of hammering if

it can be adapted to wind, water, steam or other post-apocalyptic

power supply. Another machine that will be greatly useful is a

metal lathe... preferably a large one with as many accessories as

possible. Most of them will be electric, but there are ways to

supply limited electricity in a post-apocalyptic world.

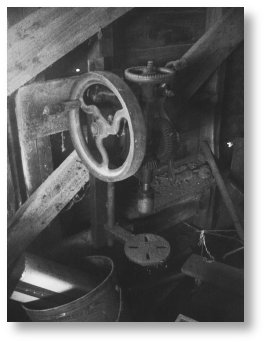

Traditional machines that are useful include treadle

grinding wheels and post drills, which are a kind of

old-fashioned drill press with a hand crank. Time was when every

farm in the country had both of these items in a shed somewhere

and often they can still be found there, covered with rust and

with wooden parts rotted to nothing.

Traditional machines that are useful include treadle

grinding wheels and post drills, which are a kind of

old-fashioned drill press with a hand crank. Time was when every

farm in the country had both of these items in a shed somewhere

and often they can still be found there, covered with rust and

with wooden parts rotted to nothing.

The post drill at right was missing a few parts, covered with

accumulated grime, and not very well mounted to the wall of this

work shop when I first laid eyes on it. I was able to place

it back into service with relatively little effort.

Currently it is "in trust" to me, pending its return to the

farmer who owns it. As he normally borrows my electric

drill press when he needs it, his post drill may be in my garage

for some time to come.

Keep your electric tools; drills, saws, grinders, etc. You can

still use them as I type this. I know this because I am using a

computer to type it on. For a while... possibly a long while...

electricity will continue to be available and electric tools are

of immense value in speeding the construction of a home, if one

needs to be built, a smithy, sheds, greenhouses, and other

structures and/or projects. There are also ways of producing

post-apocalyptic electricity for your power tools addressed in

other areas of Miles’ site.

I have made much mention and emphasis on post-apocalyptic issues

in this article. As I was writing this for Miles, I thought this

appropriate, but the principals can and perhaps should be applied

outside of a post-apocalyptic scenario as well. By definition,

the apocalypse is at a time no one knows. It will come as a

"thief in the night." How then can one prepare?

First, trust God. Second, don't worry. If you are able to get

prepared in time for the coming changes, so much the better. If

you get killed in the first nuclear exchange, you have nothing to

worry about anyway... not that it would do you any good at that

point.

Living "off the grid" is, in fact, its own reward. Slavery was

never actually abolished, you know. Only the form of it was

changed. We are all still slaves in many ways. We have to work

for a "master" in order to make money in order to pay for our

living expenses. We have to take rudeness, unpleasant working

conditions, and other nastiness as a matter of course. We never

seem to get out of the rut we have dug for ourselves. This is by

design... and started early in the last century. It is a

difficult cycle to break, but break it we can, if we really want

to.

The best way to cope with a post-apocalyptic world is to start

living in the way you would have to live then as soon as

possible. On the day the bombs fall, an Amish farmer will likely

look at the distant mushroom clouds, shrug his shoulders, perhaps

mutter "Gott in Himmel!", say a prayer, then urge the horse on to

the farm yard. He probably won't be milking cows much longer for

a living due to the changes in the economic system, but

otherwise, he has plenty of Kerosene and appliances that use

them. He won't miss the electricity as he doesn't use it, and he

won't care about the EMP that fried all the radio and television

stations. His life, and the lives of his family will probably go

on. He may have problems he might not otherwise have had, but the

basic living skills are already there and he is an expert.

We should all become experts... while there is still time, and

the best way is to simply go out and do it.

Chapter

II, Learning the Art

K, so you've managed to beg, borrow, purchase or steal

(just an expression... you wanna try to steal my blacksmith

shop... by all means go ahead and try!) all the required tools to

set up a smithy. Congratulations, you're ready to become an

apprentice. An apprentice is one step above an idiot, and even

that only by virtue of the fact that he has decided he wants to

be a blacksmith.

K, so you've managed to beg, borrow, purchase or steal

(just an expression... you wanna try to steal my blacksmith

shop... by all means go ahead and try!) all the required tools to

set up a smithy. Congratulations, you're ready to become an

apprentice. An apprentice is one step above an idiot, and even

that only by virtue of the fact that he has decided he wants to

be a blacksmith.

The absolute best way to learn the smithing trade is to find a

Master Smith who is willing to undergo the many headaches

associated with training such an individual who wishes to

learn... or at least thinks he wishes to learn. Many modern

apprentices quickly discover that blacksmithing is not an easy

way to make a living, nor is it a simple task to learn. As an

apprentice, you will find yourself doing all sorts of things that

will make you think that the Master Smith training you is in fact

Satan himself... especially the first week. You will become

familiar with a great wealth of detail exactly what the phrase

"hands on training" means... and each one of your blisters will

remind you every day of that first week.

It might help to understand the Master Smith's reasoning. Most

Master Smiths have been at this for quite some time. They have

the muscles, the callouses, the scars, and, most importantly, the

experience to prove it. They've also trained, or attempted to

train a modern apprentice or two... often to their eventual

regret. If you want to be trained as a blacksmith... be prepared

to pay for the privilege. A Master Smith's time is valuable.

The smith will invest a good deal of time in training an

apprentice, much of this training is accomplished in that first

week. The apprentice will learn to build and tend a fire, the

names of tools... which he will be fetching constantly. He'll

learn the meaning of the phrase "black heat", at some point.

He'll also find out in that week of Hell whether or not he really

wants to be a blacksmith or not. The Master Smith will find this

out as well... and he normally has no patience for slow learners.

You will get yelled at as an apprentice. This is something most

modern schools do not teach their students, which is a sad thing.

You're an apprentice, so get used to it. Figure the first week is

one of testing... if you pass, great. You pass by not quitting.

Most young apprentices give up and quit. This is a sad commentary

on our youth, but it is often true nevertheless.

By the end of the first week, you will have learned a great

deal... but don't get cocky... you're still just a newly-trained

apprentice with excrement for brains, as far as the Master Smith

is concerned. Over the next few months and years... if you make

it through the first week... your knowledge and skill will

increase such that you may become a journeyman. The exact point

at which this occurs is difficult to determine. On the day that

the smith gives you some payment for your work, you have

officially become a journeyman. You can permit yourself exactly

one and one half seconds of pride in this... then get back to

work. Time is money... or what passes for money in the

post-apocalyptic world.

I have been doing this on and off for nigh onto twenty years. I

do not consider myself a Master Smith. In fact, I probably am not

much of a journeyman, in real terms. The gaps in my knowledge are

too great to be of any real use to a Master Smith other than as a

half-trained apprentice. I call myself a "shade tree blacksmith",

or "hobby smith". Even this is a bit pretentious of me.

Most modern smiths will never achieve that exalted title of

"Master Smith", though quite a few will claim it. If you ever

reach a point where there is nothing else to learn, some

apprentice will teach you something new and you'll realize that

you really have not mastered your craft yet. When you have

reached a point where you know more than half of the things you

need to know as a blacksmith, perhaps then you can call yourself

a "Master Smith". It is always better to wait until another

Master Smith tells you this, though. He can see not only how much

you have learned, but also how much you have yet to learn and so

he is a better judge of your progression.

Most modern smiths will never achieve that exalted title of

"Master Smith", though quite a few will claim it. If you ever

reach a point where there is nothing else to learn, some

apprentice will teach you something new and you'll realize that

you really have not mastered your craft yet. When you have

reached a point where you know more than half of the things you

need to know as a blacksmith, perhaps then you can call yourself

a "Master Smith". It is always better to wait until another

Master Smith tells you this, though. He can see not only how much

you have learned, but also how much you have yet to learn and so

he is a better judge of your progression.

An important maxim: "A Master Smith is always learning... if he

ever stops learning, get a shovel, for he has expired."

There are a few schools that teach blacksmithing, though not as

many as there used to be. If you've got the time, the money, and

the inclination, go for it! Plan on learning much more than just

blacksmithing, however, and also plan on having gaps in your

education that a true apprenticeship would not leave you with.

You'll learn technical math, for example, but you probably won't

learn how to use a coal forge. You'll learn how to weld with

various types of electric and gas welders, but you may not learn

how to weld in a forge. Yes... you can weld iron and steel in a

traditional forge. How do you think welds were made before the

oxy-acetylene welding torch was invented?

The third way to learn blacksmithing is the least satisfactory,

but probably the most widely practiced these days. It is learning

by doing. This is the way I learned.

About twenty years ago, I ran across a book in the public library

called "The Art of

Blacksmithing", by Alex W. Bealer. I found it fascinating.

I read it cover to cover and renewed it for an extra month. My

first forge was an iron box that had previously been soldered

together and used metal window screen for a grate and an electric

hair-drier to provide draft. This did not work very well, as one

might imagine.

I built a second forge out of metal pipe, wood, and brick held up

on a metal frame. While more satisfactory than the first, it

still left much to be desired, and I built a progression of other

forges, each more or less superior to the previous model over the

next several years.

My first anvil was a section of railroad track, which worked

quite well, all things considered. My second was an actual London

pattern anvil, but it had been made of cast iron, and it broke

when I hammered on it. My third and final anvil is the one I use

now.

I made my first pair of tongs using some scrap iron I found in

the garage. They are not pretty, about what you'd expect from an

untrained apprentice, but I still have them today and I still use

them. After reading Alex's book, most of my learning came from my

own experimentation and from watching other smiths work. I am

still learning, and I hope I never stop learning.

If you find yourself in the final category of learning methods,

take heart, for you are in very good company indeed. The first

blacksmith did not have Alex's book. He did not have a steel

hammer, a forge, or a steel anvil. He learned much as you will,

by personal experimentation. We don't know that man's first

name.... but we know his last name; Smith, or Schmidt, or

Schmitt, or Smit, or any of a number of other variations

depending upon the nationality of the individual. Next time you

are introduced to a Mr. Smith, shake his hand with a bit of

pride, for you are meeting someone descended from a Very

Important Person.

Many a post-apocalyptic smith will quite probably fit into this

final category as well. Most probably he hasn't had the

opportunity to prepare himself for life in the post-apocalyptic

world... like many of the rest of us. He'll learn blacksmithing

because the blade on his hoe is worn out or broken, and he'll

probably ruin his first attempts to repair anything. If he is

persistent, he'll learn however.

Chapter

III, Basic Forging Operations

K, so now you have either completed some course of study

or read a few books on the subject. If you are very smart indeed,

you have now realized how much you have to learn and have either

abandoned all hope of ever joining the ranks of even the "shade

tree blacksmiths", or you think you are ready to start working

iron. If you are still reading this, perhaps you are in the final

group. If you are not very smart, continue to read as even you

may glean something from this... hey, even I learned how to do

it, nicht wahr?

K, so now you have either completed some course of study

or read a few books on the subject. If you are very smart indeed,

you have now realized how much you have to learn and have either

abandoned all hope of ever joining the ranks of even the "shade

tree blacksmiths", or you think you are ready to start working

iron. If you are still reading this, perhaps you are in the final

group. If you are not very smart, continue to read as even you

may glean something from this... hey, even I learned how to do

it, nicht wahr?

The first thing you need to do is go out and get yourself some

moleskins, Bandaids, and tincture of iodine. Unless you are a

professional carpenter, mason, or other tradesman who works with

his hands, you are going to have blisters. It usually takes me a

couple of weeks in the Spring to develop callouses on my hands

such that I no longer get blisters from hammering. No pain, no

gain.

I have assumed that the reader has been able to obtain a forge

somehow. The ways and means of building forges is beyond the

scope of this article. Look in your blacksmithing books for

examples. There are many on line articles on the subject as

well.

Excuse me, I have to go and stir the beans for the chili. OK, I'm

back again.

Fire management is a basic skill acquired early by an apprentice

that does not enjoy getting yelled at constantly. You want the

forge fire to be centered over the grate so you start the fire by

packing coal around a four-by-four block placed over it. You pack

the coal, which should be wet and finely ground almost to a

powder, to a depth of six inches or so.

Start the fire with wood shavings and small pieces of wood in a

sort of tepee fire lay down in the hole formed by the

four-by-four, which should now be removed. Try to avoid using

Kerosene to start your forge fire... Kerosene will be sought

after in the post-apocalyptic world for other purposes, such as

lighting, heating, and cooking. Learn to start a fire with birch

bark, wood shavings, and pine sticks... known as tinder and

kindling. Popsicle sticks work great if you can get them. You can

use the ubiquitous Bic butane lighter for igniting your tinder,

but you will find that a wooden match works better, if you have a

good supply of them. They are cheap now, but they won't be when

the supply runs out, so stock up.

When the tinder catches fire, go ahead and start providing a

draft from the rotary blower, bellows, or whatever provides your

draft. This should be done very slowly at first and gradually

building up as the kindling starts. You then push the coal toward

the center of the forge and increase the draft. By now the fire

should be "roaring". It will produce quite a bit of black smoke

as the tar and other impurities are burned off leaving "coke",

which is almost pure carbon, behind. Coke is what you want to use

to heat your iron, and you will continually be producing it as

you work.

Within a few moments, your fire will be ready to work.

Probably the first basic smithing operation that everyone learns

is called "drawing out". No, this does not involve a pencil,

triangle and T-square, though the related field of mechanical

drawing would not be a bad sideline to have at your disposal.

Some day you might be called upon to make a steam engine from a

set of 1875 blueprints.

Drawing out is the process of forming work by hammering it on the

face of the anvil while it is at red heat, in a "plastic" state.

A length of iron bar stock is thus made longer and thinner by

this process. You heat a section of the bar and work it, flipping

it ninety degrees after a few blows have been landed, to repeat

the process again.

To sort of "get the hang of it", you might want to get yourself

some oil clay commonly available at any art supply store... or

any other fairly stiff putty-like material. Roll the clay out

into a long piece of round "stock" and let it cool for a while in

the refrigerator. Take it out and try to work it with a toy

plastic hammer. You can use your regular anvil, or the kitchen

table, if the female half of the household will allow it. This

will give you a rough idea of how iron behaves in a plastic state

without burning any coal.

When you flip the work, allow your hammer to fall to the anvil

surface and rebound for one stroke. Don't actually apply any

force to the blow, just let it fall from its own weight. This

allows your arm to get a short rest and also helps to remove the

scale, that dark material that flakes off the hot iron as you

hammer it. It also causes the anvil to ring. Take your choice of

the reasons to hit the anvil while the work is being flipped. Any

one of them is just OK... and all smiths do this for one reason

or another... the reason varying with the smith.

A good first project for a new smith is a "rake". A rake is a

tool used by the blacksmith, or quite likely the apprentice, to

move lumps of coal, or other objects around in the forge. It is a

rod of metal with a short flattened bend on the working end, and

an elongated loop on the handle end. It needs to be long enough

so that you can handle it without burning yourself on it. About

24 inches length overall is about right. Some smiths actually use

something more akin to a garden rake with small tines, but I have

found my simple rake to be quite sufficient.

The use of this tool gave rise to the phrase "raking over the

coals", meaning to make someone uncomfortable.

Another good project is a fireplace poker... which can double as

the forge rake, for those short of iron stock.

You'll note that the finished work will be black in color. This

is where the term "blacksmith" comes from. Iron as it was

traditionally worked, was called "the black metal". "Smith" comes

from the verb "smite", as in to smite the black metal. Hence:

blacksmith.

Another catch phrase even in modern culture is "to strike while

the iron is hot", meaning to take advantage of a transient

condition of opportunity. Iron is normally worked at "red heat".

So... what does that mean exactly?

Well, in theory, Iron can be worked at any temperature, and in

some applications, medieval armor, for example, is worked cold.

There are problems with cold working bar stock however. First and

foremost, you will quickly run out of energy trying to forge cold

bar stock. Second, if you do manage to work it while cold, you

will end up with a piece of iron that is so work hardened and

loaded with internal stresses, that it will likely break at the

first application you put it to. This is especially important

when forging something like a sword or other knife blade.

So strike while the iron is hot. It may have occurred to you by

now that you have to work quickly. If it has, you are correct in

your presumption.

Heat is traditionally gaged by color, and the proper forging heat

will vary with the type of material being worked. Most mild

steel, used for 90% of the work most smiths do, works best at a

bright yellow-orange to a red-orange color. When it gets to a

dull red color, it has cooled too much and must be reheated for

further working. Forging temperature is not nearly as critical as

that of welding or hardening and tempering. If you get it so hot,

that sparks fly out of the forge, you have gotten it too hot.

This is what is termed "white heat", and is the temperature used

for welding. You can burn your work like this and if you do, you

will have to discard that piece of metal and start over. The

smaller the work becomes, the more critical this is because

smaller work heats up much faster.

A word about "black heat". Recently forged iron holds its

temperature for quite a while after it is taken out of the fire.

One will obviously be careful about picking up a piece of work

that is still glowing red, but an inexperienced individual might

simply grab onto a piece of black iron laying on the anvil. That

piece of iron can be hot enough to make a piece of wood burst

into flame. Think what it could do to your hand. Good rule of

thumb: when you are visiting another smith's shop, don't touch

anything unless he hands it to you... if it didn't burn his

hands, it won't burn yours either.

An experienced smith upon reaching for a piece of iron for which

he is unsure of the temperature, will invariably hold his hand

over it first to see if he can feel any heat, then he will touch

it quickly and pull his hand away... perhaps a few times...

before picking it up. If the iron is very hot, it will sear the

nerve endings so fast that there is no time for the pain to get

to the brain. The nerve endings a little further up the network

will fire before they die though... but not fast enough to keep

you from blistering your hand. If you are fortunate, your skin

and the flesh beneath will not stick to the metal when you scream

and pull your hand away.

Iron works HOT. Never forget that.

You'll gradually lengthen and thin the bar to the required

specifications and end (hopefully) with a square piece of bar

stock that has some hammer texture, a black surface, and is the

proper length for the required usage. Try to avoid getting it

into a trapezoidal shape... unless you are actually trying to do

that. Hint: if you end up with a trapezoidal cross section...

claim you wanted it that way! Once a bar has gotten started in a

trapezoidal shape, it requires a good deal of effort to correct.

Keep your blows square to each other.

A point is formed by gradually tapering the work down. You

can make it as gradual or as abrupt as you wish. I start tapering

my storage hooks about three inches from the end and bring 'em to

a fairly sharp point. This is not necessary, and it may be

desirable to avoid sharp hooks, especially when they are destined

to be placed where someone might injure himself on it. Hint:

don't hang wall hooks at eye level if it can be avoided.

A point is formed by gradually tapering the work down. You

can make it as gradual or as abrupt as you wish. I start tapering

my storage hooks about three inches from the end and bring 'em to

a fairly sharp point. This is not necessary, and it may be

desirable to avoid sharp hooks, especially when they are destined

to be placed where someone might injure himself on it. Hint:

don't hang wall hooks at eye level if it can be avoided.

Bending can be accomplished in any one of several ways. It seems

fairly straight-forward, but it can be the most frustrating

experience a new smith can have, perhaps because it seems so

simple. That pointed end of the anvil is called the "horn", and

one of the primary uses it has is for bending the iron being

worked. It can be used with light blows close to the pivot point

to make for a gradual curve, or further from the pivot point to

produce a more abrupt bend. Bending on the horn is not as easy as

one might think. I will just about guarantee that your first bend

will be misaligned. Don't panic, you can flatten it out on the

anvil's face to correct your mistake.

The elongated loop for the handle of your rake is normally forged

on the horn. Figure that you need about two inches more than the

length of the loop you plan to make. Measure that distance...

about a hand's breadth... from the end and add three inches for

the bend and mark it with a piece of soapstone. Heat the area

just beyond the mark and then make your bend either over the horn

or by simply bending it with tongs. You can either make a

teardrop shaped loop or a "square handle". If you wish to do the

teardrop handle, you need to put a scarf on the end of the rod

before you make the U bend. If you want a square handle, just

bend the rod until it becomes parallel to itself and then heat

the end of it and bend the rod until it touches itself. You can

weld this joint... and it is fairly easy to do if you have a

teardrop shape and have properly scarfed the end of the rod. This

is not necessary, however.

At this point, you should have a fairly usable rake and are ready

to move on to other things.

What other things? The sky is the limit!

Drawing out is probably the most common forging operation, but it

is not the only one. A second operation is called "upsetting".

While drawing out thins and lengthens the work stock, upsetting

does the opposite; it shortens and thickens the stock.

There are various techniques for upsetting. One of the most

interesting is to simply heat the end of the rod you want to

upset and then drop it onto a hard surface such that it hits

longitudinally. The momentum of the rod itself supplies the force

of the blow. This can be repeated as many times as necessary to

achieve the desired thickness. This method is rather difficult to

control however. You will often find that the work will bend as

well as being upset.

Other methods involve hammering on the heated end of the

workpiece to facilitate upsetting, and bracing the heated end

against the anvil face and hammering the other end. These both

work to some extent, but also suffer from a tendency to bend the

work.

The Complete Modern

Blacksmith has an excellent section on upsetting. There

are techniques there for correcting the above mentioned bends.

The use of an upsetting matrix, also shown in this book, greatly

reduces the tendency to bend the work while upsetting.

Why would you want to upset a piece of work in the first place?

Well, for things like wall hooks, as I make them, you wouldn't.

Likewise for many other implements. But suppose you wanted to

make a bolt with a head on it? I suppose that you could forge the

shaft and the head separately, but handling such a small piece as

a bolt head... and especially at welding heat, is almost an

exercise in frustration. Even if you somehow manage it as a new

smith, quite possibly the weld will be imperfect and will break

when torque is applied to it. Much better to upset the head from

the shaft in an upsetting matrix and then refine the shoulder

with a header plate. Once this is accomplished, one can forge the

square or hexagonal bolt head. I would highly suggest the square

bolt head for beginners... they are much easier to do. Carriage

bolts are made similarly, but with a square-holed header

plate.

Fullering is a specialized form of drawing out. It involves the

use of a tool that looks like a chisel with a rounded over

working surface. To use it, one simply places the working surface

over the workpiece and hammers it into the metal. This will make

a (hopefully) shallow impression on the work, thinning it and

lengthening it, but not appreciably increasing the width. This is

repeated for the entire length of the workpiece. The finishing

operation involves forging the high spots down to the level of

the impression, thus forming... perhaps... a blank for a knife

blade or similar implement. Fullering can also be done with the

peen of a hammer... so long as it is not too sharp. Another type

of fuller fits into the hardy hole of the anvil and the metal is

placed on top of it and struck with the hammer.

I have never found fullering to be all that useful... but then, I

don't normally make knives from round or square bar stock. Still,

it is an available technique.

Twists are formed by holding one end of a workpiece that has been

heated and twisting the other end of it. You either need an

apprentice, or you need to get creative. If the implement to have

the twist applied to it has a bend in it as a forge rake or wall

hook, one can put the bend into the pritchel hole or hardy hole

of the anvil and twist the other end. If it does not have such a

bend, you need something like a vise to hold it.

I have a metal work table (rummage sale $5.00) that

has a few holes drilled in it that I sometimes use for twisting.

This method has the advantage of having the relatively true work

surface to use as a gage to avoid unwanted bends in the section

getting the twist as I can keep the workpiece relatively parallel

to the table top. You also may need some kind of gripping tool to

apply twists for some applications. Tongs will work, but I have a

couple of old-fashioned monkey-wrenches (photo at left) that work

quite well for this. The jaws can be adjusted to fit the metal

and then used without fear of having the work twist out of the

grip. I've seen one of these wrenches with another piece of metal

welded onto it to form an adjustable "T" handle. I haven't tried

that yet, but it should work rather well as you would have more

control over the workpiece, not to mention added leverage.

I have a metal work table (rummage sale $5.00) that

has a few holes drilled in it that I sometimes use for twisting.

This method has the advantage of having the relatively true work

surface to use as a gage to avoid unwanted bends in the section

getting the twist as I can keep the workpiece relatively parallel

to the table top. You also may need some kind of gripping tool to

apply twists for some applications. Tongs will work, but I have a

couple of old-fashioned monkey-wrenches (photo at left) that work

quite well for this. The jaws can be adjusted to fit the metal

and then used without fear of having the work twist out of the

grip. I've seen one of these wrenches with another piece of metal

welded onto it to form an adjustable "T" handle. I haven't tried

that yet, but it should work rather well as you would have more

control over the workpiece, not to mention added leverage.

Bends will sometimes manifest themselves in a twist. They can be

dealt with. You can't really correct them very well on an anvil

with a hammer in the way you would a bend developed while drawing

out as you will cause flats to form on the twisted section. I

usually correct them by laying a small piece of plywood on the

anvil and then using a brass hammer to correct the bend against

the plywood. The plywood will burn, but it and the brass hammer

are usually soft enough to avoid flats and hard enough to allow

for the bend correction. Another technique I have found useful is

a wooden mallet and a large section of a tree trunk or stump.

This makes for much smoke, but never produces any flats on the

twist. It also does not leave any brass residue on the

work.

I have placed a short Windows Media clip here that demonstrates a few

techniques. Video quality could be better, but it does

serve to show drawing out, twisting, and correcting a bend in a

twist.

Most twists, such as those put in a fireplace poker's handle, are

purely decorative. Whether or not the post-apocalyptic smith

would utilize his limited resources of time and coal to produce

such things would depend upon circumstances. I suspect that most

smiths would still do some decorative work on their products...

decorative work tends to fetch a higher price in the market

place.

Market considerations will still be important in the

post-apocalyptic world... though the relative values of things

will likely be skewed from where they are now. In some places a

bride's dowry is still commonly paid to the new husband by the

bride's family. In the post-apocalyptic world, surviving women

may be a bit scarce... conditions being harsh. If you want a

healthy young wife, for example, (this is assuming, of course,

that you are not an ornery old man such as myself, but rather a

youngster intent on starting a family) you may end up having to

pay her father. It is easier to make twenty decorative pieces

than it is to make forty plain ones in exchange for the hand of

the same woman. If she is beautiful and/or exotic, you might have

to pay even more, further enhancing the added value of your

labor.

My solution would be to court her older sister, who might not be

as pretty, but probably is smarter and possibly not as flaky...

and maybe only have to produce ten decorative items. If she is a

widow with kids (a definite possibility in this kind of world),

so much the better! Older children are infinitely useful around a

smithy!

Some twists are not decorative, however, but are actually one of

the basic simple machines known as the screw. Certainly you can